stainless steel filter screen

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 10,000 square meter per week |

| Place of Origin: | Hebei |

Company Profile

| Location: | Langfang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Stainless Steel Filter Screens, Crimped Wire Meshes, Polyester Screens, Stainless Steel Printing Screens, Brass Wire Mesh |

Product Detail

| Model No.: | NAN-SP |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Style: | Others |

| Material: | Others |

| Use: | Others |

| Brand Name: | BJPFM |

| material: | stainless steel 304 304L 316 316L |

| use: | filtration |

| name: | stainless steel filter screen |

| Production Capacity: | 10,000 square meter per week |

| Packing: | palstic bag inside carton bag outside or according to the customer`srequirement |

| Delivery Date: | in 3 to 5 days for goods in store |

Product Description

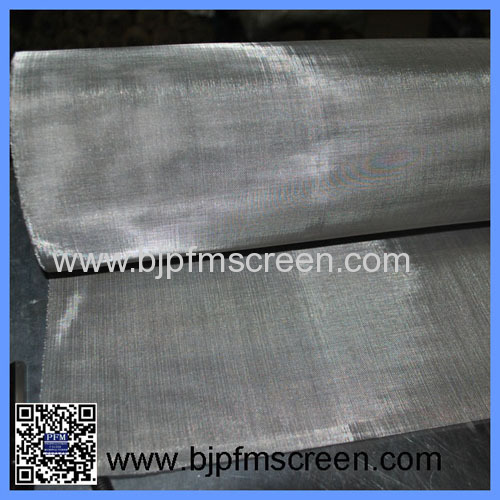

stainless steel filter screen

Description:Stainless steel filter screenrefers to the stainless steel wire cloth used for screening of solid perticles,powers and dust,etc.

Material:SUS304,304L 316,316L Weave:Plain weave,twill weave, dutch weave,twill dutch weave ,reverse dutch weave.

Weave:Plain weave,twill weave, dutch weave,twill dutch weave ,reverse dutch weave.

Plain Weave Wire Cloth is the most commonly used and simplest wire cloth weave. Each weftwire is woven alternately over and under the warp wires through the cloth at 90 degree angles. It is a very common weave that can be produced quickly and economically. It has a wide range of applications.

Twilled Weave Wire Cloth is woven by passing each weft wire alternately over and under two warp wires. This type of weave is commercially woven in items ranging from 150-635 mesh .However, it is also available in course and mid range mesh combinations.

Wire Diameter | Aperture | Open Area | Weight(kg/Square meter) | |||

Inch | MM | Inch | MM | |||

1×1 | 0.080 | 2.03 | 0.920 | 23.37 | 92.0 | 2.0 |

2×2 | 0.063 | 1.60 | 0.437 | 11.10 | 87.4 | 2.5 |

3×3 | 0.054 | 1.37 | 0.279 | 7.09 | 83.8 | 2.7 |

4×4 | 0.047 | 1.2 | 0.203 | 5.16 | 81.2 | 2.7 |

5×5 | 0.041 | 1.04 | 0.159 | 4.04 | 79.5 | 2.6 |

10×10 | 0.024 | 0.6 | 0.076 | 1.94 | 74.9 | 1.8 |

12×12 | 0.020 | 0.5 | 0.064 | 1.62 | 75.9 | 1.5 |

14×14 | 0.020 | 0.5 | 0.052 | 1.314 | 71.9 | 1.75 |

16×16 | 0.018 | 0.45 | 0.045 | 1.137 | 71.2 | 1.6 |

18×18 | 0.016 | 0.4 | 0.0398 | 1.01 | 69.4 | 1.4 |

20×20 | 0.009 | 0.24 | 0.041 | 1.03 | 76.0 | 0.57 |

20×20 | 0.012 | 0.3 | 0.0382 | 0.97 | 72.2 | 0.9 |

30×30 | 0.012 | 0.30 | 0.0215 | 0.547 | 63.9 | 1.35 |

30×30 | 0.0094 | 0.24 | 0.0243 | 0.62 | 72.1 | 0.84 |

40×40 | 0.0098 | 0.25 | 0.015 | 0.385 | 36.74 | 1.25 |

50×50 | 0.0079 | 0.20 | 0.0121 | 0.308 | 36.7 | 1.0 |

60×60 | 0.0047 | 0.12 | 0.012 | 0.303 | 71.6 | 0.42 |

60×60 | 0.0059 | 0.15 | 0.0107 | 0.273 | 64.5 | 0.65 |

80×80 | 0.0047 | 0.12 | 0.0078 | 0.198 | 38.7 | 0.58 |

80×80 | 0.0055 | 0.14 | 0.0069 | 0.177 | 45.5 | 0.76 |

100×100 | 0.0039 | 0.10 | 0.006 | 0.154 | 59.8 | 0.50 |

100×100 | 0.0043 | 0.11 | 0.0056 | 0.144 | 55.1 | 0.60 |

120×120 | 0.0027 | 0.07 | 0.0056 | 0.142 | 67.7 | 0.29 |

120×120 | 0.0031 | 0.08 | 0.0052 | 0.132 | 38.7 | 0.38 |

150×150 | 0.0024 | 0.06 | 0.0043 | 0.109 | 41.6 | 0.27 |

165×165 | 0.0018 | 0.045 | 0.0043 | 0.109 | 50 | 0.167 |

180×180 | 0.0019 | 0.05 | 0.0036 | 0.091 | 64.5 | 0.22 |

180×180 | 0.0023 | 0.06 | 0.0032 | 0.081 | 57.4 | 0.32 |

200×200 | 0.0019 | 0.05 | 0.003 | 0.077 | 60.6 | 0.24 |

200×200 | 0.0024 | 0.06 | 0.0026 | 0.067 | 52.7 | 0.35 |

250×250 | 0.0012 | 0.03 | 0.0028 | 0.072 | 49.8 | 0.11 |

250×250 | 0.0016 | 0.04 | 0.0024 | 0.062 | 36.9 | 0.20 |

270×270 | 0.0014 | 0.035 | 0.0023 | 0.059 | 60 | 0.16 |

270×270 | 0.0016 | 0.04 | 0.0021 | 0.054 | 57.4 | 0.21 |

300×300 | 0.0012 | 0.03 | 0.0022 | 0.055 | 57 | 0.13 |

325×325 | 0.0014 | 0.035 | 0.0017 | 0.0432 | 55.3 | 0.20 |

400×400 | 0.0012 | 0.03 | 0.0013 | 0.0335 | 52.7 | 0.18 |

500×500 | 0.0009 | 0.025 | 0.001 | 0.0258 | 50.7 | 0.15 |

635×635 | 0.0007 | 0.018 | 0.0008 | 0.022 | 55.0 | 0.10 |

Dutch Weave Wire Cloth is woven with a larger wire diameter in the warp direction and a relatively smaller wire in the shute direction. This weave has great strength and is available in wide range of micron ranges. It is primarily used to filter a wide range of liquid and slurry products. Twilled Dutch Weave Wire Cloth is a woven product that is capable of very fine filtration. Warp wires are passed alternately over and under two warp wires forming a fine mesh. It has a wide range of filtration applications for gas and liquid applications.

Twilled Dutch Weave Wire Cloth is a woven product that is capable of very fine filtration. Warp wires are passed alternately over and under two warp wires forming a fine mesh. It has a wide range of filtration applications for gas and liquid applications.

Wirediameter(mm) | Aperture(micron) | |

20*250 | 0.28*0.2 | 38 |

30*300 | 0.25*0.18 | 36 |

50*500 | 0.14*0.11 | 34 |

80*700 | 0.11*0.18 | 32 |

80*780 | 0.10*0.07 | 30 |

90*780 | 0.10*0.07 | 25 |

100*780 | 0.10*0.07 | 22 |

100*900 | 0.10*0.063 | 20 |

120*1100 | 0.07*0.05 | 17 |

150*1400 | 0.063*0.04 | 16 |

180*1800 | 0.07*0.04 | 14 |

165*1400 | 0.063*0.032 | 13 |

200*1400 | 0.07*0.04 | 12 |

200*1800 | 0.05*0.032 | 10 |

210*1900 | 0.045*0.03 | 10 |

250*2000 | 0.045*0.028 | 8 |

280*2200 | 0.036*0.026 | 7 |

300*2200 | 0.036*0.026 | 6 |

325*2300 | 0.035*0.025 | 5 |

400*2800 | 0.03*0.018 | 3 |

Reverse Dutch Weave Wire Cloth is a very strong woven product. This wire clothis ideal for making filter belts, and applications where fine filtration and great strength are required.

.jpg)

.jpg)