Polyester Printing Silk Screen Mesh

| Min. Order: | 50 Meter |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 100,000 square meters per year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Langfang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Stainless Steel Filter Screens, Crimped Wire Meshes, Polyester Screens, Stainless Steel Printing Screens, Brass Wire Mesh |

Product Detail

| Model No.: | NAN-SP |

|---|---|

| Means of Transport: | etc, Ocean, DHL, EMS, Air, TNT, Land |

| Style: | Plain |

| Pattern: | Printed |

| Width: | Others |

| Material: | 100% Polyester |

| Use: | Industrial |

| Brand Name: | BJPFM |

| Yarn Count: | Monofilament |

| Density: | as order |

| material: | Polyester |

| application: | screen printing |

| type: | plain weave |

| color: | white and yellow |

| Production Capacity: | 100,000 square meters per year |

| Packing: | plastic bag inside ,carton bags out side |

| Delivery Date: | in 3 or 5 dayes |

Product Description

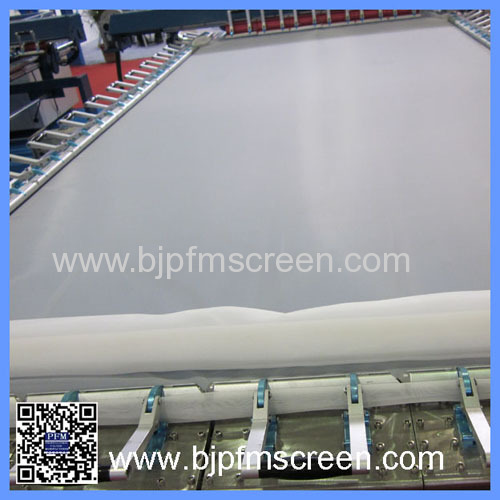

Polyester printing silk screen mesh

Brief introduct

With the high quality material,our produces superior quality polyester bolting cloth for screen printing. We also have the most advanced testing instruments and technicians well trained to guarantee a reliable quality.

PFM screen Printing Mesh is high-precision screen printing mesh , polyester mesh, rang from 6T to 165Tmesh count(15-380). It is made of imported material from Germany, woven by Switzerland technology, with optimize screen-printing performance. PFM mesh can meet the demanding needs of different industries, such as PCB, Ceramic, Waist line, Flower paper, Advertisement, Shoe, Plastic, Glass, Scutcheon, Craftwork, Handbag and Textile printing, etc.

Polyester Silk Screen Printing Mesh Applications:

Textile Printing,Graphic Screen Printing, Package Printing,Glass Printing,Ceramic Decorating,

CD/DVD Printing, PCB Printing,Electronics Printing,Solar Cell Printing,etc.

Specification of polyester printing silk screen mesh

Material:100% polyester

Monofilament Screen Printing Mesh Specifications | |||||||

Model | Mesh/cm | Mesh/inch | Aperture | Thread Dia. | Open Area | Thickness | Theoretical Ink |

10-250 | 10 | 25 | 743 | 250 | 55 | 495 | 274 |

12-140 | 12 | 30 | 686 | 140 | 68 | 277 | 189 |

13-150 | 13 | 33 | 619 | 150 | 64 | 300 | 128 |

16-140 | 16 | 40 | 461 | 140 | 58 | 238 | 139 |

21-80 | 21 | 55 | 296 | 80 | 69 | 120 | 79 |

21-150 | 21 | 55 | 326 | 150 | 46 | 260 | 118 |

22-80 | 22 | 56 | 356 | 80 | 66 | 136 | 90 |

24-80 | 24 | 60 | 320 | 80 | 63 | 136 | 86 |

24-100 | 24 | 60 | 316 | 100 | 57 | 170 | 65 |

28-140 | 28 | 70 | 217 | 140 | 40 | 195 | 76 |

32-55 | 32 | 80 | 257 | 55 | 67 | 103 | 67 |

32-64 | 32 | 80 | 248 | 64 | 63 | 95 | 56 |

32-100 | 32 | 80 | 212 | 100 | 46 | 170 | 73 |

36-90 | 36 | 92 | 183 | 90 | 44 | 150 | 65 |

39-55 | 39 | 100 | 177 | 55 | 56 | 88 | 55 |

43-80 | 43 | 110 | 149 | 80 | 41 | 130 | 53 |

47-55 | 47 | 120 | 152 | 55 | 51 | 88 | 48 |

48-70 | 48 | 122 | 133 | 70 | 41 | 115 | 47 |

53-55 | 53 | 135 | 133 | 55 | 50 | 86 | 42 |

54-64 | 54 | 137 | 115 | 64 | 39 | 100 | 39 |

54-70 | 54 | 137 | 109 | 70 | 35 | 116 | 40 |

61-64 | 61 | 155 | 90 | 64 | 31 | 101 | 30 |

64-55 | 64 | 160 | 98 | 55 | 38 | 98 | 36 |

64-64 | 64 | 160 | 85 | 64 | 30 | 115 | 34 |

68-55 | 68 | 175 | 85 | 55 | 34 | 85 | 28 |

68-64 | 68 | 175 | 78 | 64 | 28 | 105 | 30 |

72-48 | 72 | 182 | 90 | 48 | 36 | 78 | 33 |

72-55 | 72 | 182 | 85 | 55 | 30 | 90 | 27 |

80-48 | 80 | 200 | 72 | 48 | 33 | 74 | 25 |

90-48 | 90 | 230 | 56 | 48 | 25 | 78 | 19 |

100-40 | 100 | 255 | 58 | 40 | 33 | 63 | 21 |

110-40 | 110 | 280 | 48 | 40 | 27 | 64 | 17 |

120-31 | 120 | 305 | 49 | 31 | 35 | 49 | 17 |

120-34 | 120 | 305 | 45 | 34 | 30 | 55 | 16 |

130-34 | 130 | 330 | 40 | 34 | 27 | 55 | 15 |

140-31 | 140 | 355 | 36 | 31 | 26 | 48 | 12 |

140-34 | 140 | 355 | 31 | 34 | 20 | 53 | 10 |

150-31 | 150 | 380 | 32 | 31 | 23 | 49 | 11 |

150-34 | 150 | 380 | 23 | 34 | 13 | 55 | 6.5 |

165-31 | 165 | 420 | 23 | 31 | 15 | 48 | 7 |

Note:The above theoretic data is for reference only,and thickness tollerance | |||||||

Polyester Printing Silk Screen Mesh Characteristics:

1.Faster tensioning without damage to the threads

2.Improved fabric strength

3.Faster tension stabilization

4.Higher tension threshold and breaking point

5.Less tension loss during the stretching process

6.Faster turnaround time from the screen room to the pressroom

7.Improved registration due to stable tension

8.Faster Print Speeds