Stainless Steel Printing Mesh

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | FOB,CFR,EXW |

| Payment Terms: | Paypal, T/T, paypal, WU |

| Supply Ability: | 100000 meters per month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Langfang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Stainless Steel Filter Screens, Crimped Wire Meshes, Polyester Screens, Stainless Steel Printing Screens, Brass Wire Mesh |

Product Detail

| Model No.: | NAN |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

| Application: | Filter |

| Type: | Woven |

| Material: | Others |

| Brand Name: | BJPFM |

| Mesh Size: | 1.02m,1.22m |

| Material: | SUS304N,304HPS,316L |

| Mesh/inch: | 40-400 |

| Wire Dia.: | 18-160micron |

| Thickness: | 36-320micron |

| Calendered thickness: | 23-67micron |

| Production Capacity: | 100000 meters per month |

| Packing: | Waterproof paper inside and wooden case outside |

| Delivery Date: | in 3-5days for goods in stock |

Product Description

Stainless Steel Printing Mesh

Material:SUS304N,304HPS,316L

Mesh/inch:40-400

Wire Dia.:18-160micron

Thickness:36-320micron

Calendered thickness:23-67micron

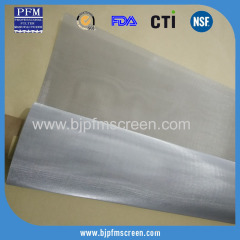

Stainless steel printing mesh is woven with high quality stainless steel wires,which results stainless steel printing screen can offer more better features than common polyester mesh in screen printing:

1.super precision,

2.low elongation,

3.high flexibility,

4.high corrosion resistance,

5.non-electiostatic,

6.good heat-melting resistance,

7.good solvent resistance.

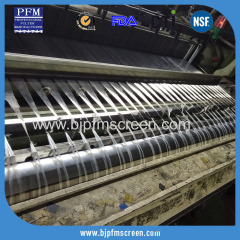

Stainless Steel Calender Printing Mesh:

Resen's calender technology achieves thin mesh with outstanding thickness uniformity and flat-lying characteristics.

1.This process enables mesh to achieve thinner thickness that is not possible with a regular woven screen.

2.Our process technology enhanced thickness uniformity/flat-lying characteristics of mesh to achieve smoother squeegeeing.

3.This stainless steel printing screen shows its capabilities in improving uniformity of film thinckness,reducing printing thickness,superior edge definition,and printing dimensional accuracy.

Applications:

1.Used for printing of Chip Electrical Components,

2.Solar battery printing,

3.High-density printed circuit board printing,

4.Liquid crystal display printing,

5.Glass printing,such glass bottle,high grade maquillage glass package bottle,

6.Textile printing,

7.Ceramics printing.