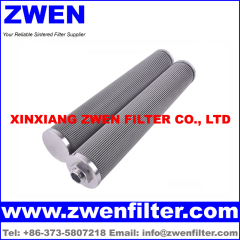

BEOT-porous metal filter cartridge

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Hebei |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Fitler Tube, Sintered Filters, Filter Tubes, Filter Disc, Filter Media |

Product Detail

| Structure: | Cartridge Filter |

|---|---|

| Function: | Water Filter |

| Material: | Others |

| Brand Name: | BEOT |

Product Description

BEOT Filter cartridge is made of sintered metal powder materials in high temperature by metallurgy process. It is produced by cold isostatically pressing and be connected directly with the main thread.

The filtration rating is made from 0.1~200 microns.

Available materials are: Stainless steel 316/316L, 304/304L, 310, 904, Titanium, Inconel, Hastelloy, Nickel, Monel and other alloys. etc. On request.

The pore size can be adjusted by suitable selection of the powder size fraction and the process parameters.

Main Application

1.Gas and liquid filtration

2.Solid catalyst recovery

3.Filtration of slurry oil and other petrochemical products

4.High-temperature gas filtration

5.Fluidization

6.Powder conveying

7. Sparging and other applications in various industrial fields.

Main advantages

1. Good shape stability

2. High mechanical strengthen and good integrity

3. Controllable pore sizes and porosity

4. Good permeability

5. Good corrosion and thermal resistance

6. Easy to be made into complicated shapes, can be put together by soldering or gluing

7. The service life can be prolonged by cleaning and regenerating process