self-operated (after-valve) pressure control valve

| Min. Order: | 1 pcs |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | 30D01Y 30D01R |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Tisun |

| Packing: | wooden carton |

| Delivery Date: | 7 dyas |

Product Description

Summary

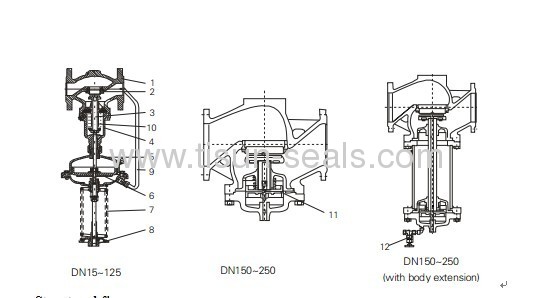

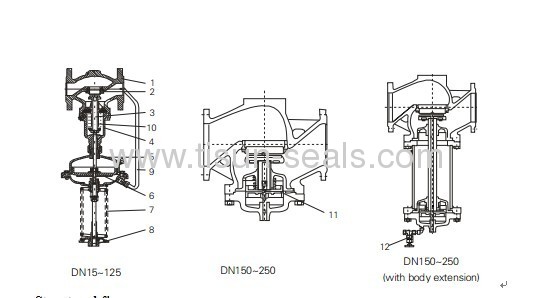

Structural figure

TheV230D01/V231D01self-operated (after-valve) pressure control valve is Composed of the control valve, actuator And a spring used for pressure setting. It is suitable for controlling after-valve Pressure in the pipes of non-corrosive liquids, gases and steams. When the after-valve pressure rises, the control Valve is closed.

The main features are as follows:

1.It has the pressure balancing function With high sensitivity.

2.Low noise, reliable performance, free Of maintenance

3.The standard modular design is adopted.

4.Various combined controls can be carried out through the assemblies.

Technical parameters and performances

Body

DN | DN15 20 25 32 40 50 65 80 100 125 200 250mm | |

PN | PN1.6 4 .0MPa | |

Flange standard | ANSIJISDIN GB JB(special standards can be offeredaccording to user requirements) | |

Body material | Cast iron (HT200), cast steel (ZG230-450), caststainless steel (ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2T i) | |

Plug material | Hard seal | Stainless steel (1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti) |

Soft seal | Stainless steel embedded with rubber ring | |

Pressure balancing | Stainless steel bellows(DN15~125), balanced diaphragm (DN150~250) | |

Actuator

Effective area (cm2) | 32 | 80 | 250 | 630 |

Pressure setting range | 0.8~1.6 0.3~1.2 | 0.1~0.6 0.05~0.3 | 0.015~0.15 0.01~0.07 | 0.005~0.035 |

Minimum differential pressure that ensures normal work of thepressure valve | ≥0.05 | ≥0.04 | ≥0.01 | ≥0.005 |

Allowable maximum differential pressure between the upper a nd lowerdiaphragm chambers | 2.0 | 1.25 | 0.4 | 0.15 |

Material | Diaphragm cover: galvanizedsteel sheet; Diaphragm: EPDM or FKM withfiber | |||

Control pipeline connection | Copper pipe or steel pipe Φ10X1(mm); Ferrule connection: R1/4" | |||

Note: The pressure setting range corresponding to the effective area does not apply to valves with DN150-250.

Performance

Set value error | ±8% | |

Allowable leakage (under stipulated testingconditions) | Hard seal | 4x0.01% valverated capacity |

Soft seal | DN15~50 DN65-DN625 DN150~250 | |

10 bubbles/ min 20 bubbles/min 40 bubbles/min | ||

30D01Y30D01R self-operated (after-valve)

Structural figure

1Body | 2Seat | 3 Valve shaft | 4 Bonnet | 5 Diaphragm | 6 Diaphragm cover |

7Spring | 8 Adjusting nut | 9 Pressure pipe | 10 Bellows | 11 Balanceddiaphragm | 12Charging valve |

Allowable working temperature

DN | 15~125mm | 150~250mm | |

seal type | Hard seal | ≤150℃ | ≤140℃ |

Cooling tank≤200℃ | Cooling tank and extension ≤200℃ | ||

Cooling tan k and heat sink ≤350℃ | Cooling tank and extension ≤300℃ | ||

Soft seal | ≤150℃ | ||

Note: It indicates the allowable working temperature is valid only when the medium is steam and theBody with PN40 shall be adopted when the temperature resistance is 350℃.

Rated flow coefficient, noise measuring coefficient, allowable differential pressure

30D01Y 30D01R self-operated (after-valve)

II. Dimensions and weight of actuator

Effective area (cm) | 32 | 80 | 250 | 630 |

R (mm) | 172 | 172 | 263 | 380 |

H (mm) | 435 | 430 | 470 | 520 |

Weight(Kg) | 7.5 | 7.5 | 13 | 28 |