.jpg)

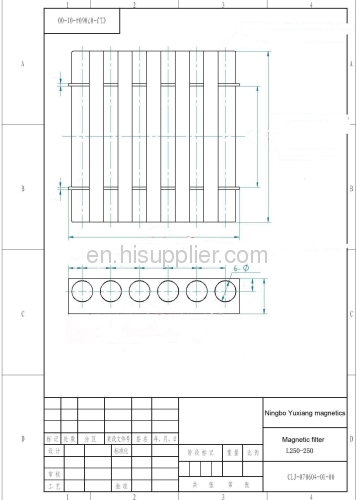

strong magnetic tube filter frame separator

0.01~100.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ndfeb Magnets, Alnico Magnets, Smco Magnets, Ferrite Magnets, Cup Magnet |

Product Detail

| Means of Transport: | By Express, Ocean, Air, Land |

|---|---|

| Structure: | Others |

| Function: | Others |

| Material: | Others |

| Brand Name: | Yuxiang magnetics |

| Material: | magnet, metal and others |

| Fuction: | Filter impurities from Water or oil or liquid |

| Production Capacity: | 10000pcs/month |

| Packing: | standard Air package and Sea package |

| Delivery Date: | 20-30 days |

Product Description

Magnetic grids are extremely efficient for removing fine iron contamination from dry free flowing powders and granulates. Magnetic grids are very versatile and can be easily placed into product intake points and at finished goods outlet points.

Magnetic grids can be installed in minutes and provide instant protection.Contamination such as rust, stainless steel scrapings and wear from machinery are often too small to be detected by a metal detector, but are easily removed by these highly efficient grids. All product contact parts are manufactured using 316 or 304 grade stainless steels.

The construction of magnetic grids

.jpg)

.jpg)