.jpg)

block sintered ndfeb anisotropic magnet

0.01~10.0 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100ton/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ndfeb Magnets, Alnico Magnets, Smco Magnets, Ferrite Magnets, Cup Magnet |

Product Detail

| Means of Transport: | By Express, Ocean, Air, Land |

|---|---|

| Application: | Industrial Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | Yuxiang magnetics |

| Material: | neodymium magnet |

| Fuction: | Block magnets are mainly used in MRI equipment, magnetic separator machine and liner motor. |

| Production Capacity: | 100ton/month |

| Packing: | standard Air package and Sea package |

| Delivery Date: | 7-15 days |

Product Description

1. This is neodymium magnet. the neodymium magnets mainly have two classification according to different production process, the sintered neodymium magnet and bonded neodymium magnet.

2. The neodymium magnets also have another name is NdFeB magnet,

Becuase it's the mainly chemical composition are neodymium(Nd), iron(Fe) and boron(B).

The picture's product is sintered NdFeB magnet.

3. Block Magnet is one regular shape of Sintered NdFeB permanent magnets.

It is always manufactured via Cutting, grinding and so on. Block magnets or Rectangle magnets have the following important factors such as, Length,Width, Thicknes, Round Edge etc.

Block magnets are mainly used in MRI equipment, magnetic separator machine and liner motors.

2. The neodymium magnets also have another name is NdFeB magnet,

Becuase it's the mainly chemical composition are neodymium(Nd), iron(Fe) and boron(B).

The picture's product is sintered NdFeB magnet.

3. Block Magnet is one regular shape of Sintered NdFeB permanent magnets.

It is always manufactured via Cutting, grinding and so on. Block magnets or Rectangle magnets have the following important factors such as, Length,Width, Thicknes, Round Edge etc.

Block magnets are mainly used in MRI equipment, magnetic separator machine and liner motors.

| Magnetic Characteristics And Physical Properties of Sintered NdFeB magnet: | |||||

| Properties | Remanence | Coercive Force | Intrinsic Coercive Force | Max Energy Product | Max Working Temp |

| Br | Hcb | Hcj | (BH)max | Tw | |

| Grade | mT(KGs) | KA/m (KGs) | KA/m (KOe) | KJ/m 3 ( MGOe ) | ℃ |

| N-30 | 1080-1130 | ≥ 796 | ≥ 955 | 223-247 | ≤ 80 |

| (10.8-11.3) | ( ≥ 10) | ( ≥ 12) | (28-31) | ||

| N-33 | 1130-1180 | ≥ 836 | ≥ 955 | 247-270 | ≤ 80 |

| (11.3-11.8) | ( ≥ 10.5) | ( ≥ 12) | (31-34) | ||

| N-35 | 1170-1220 | ≥ 868 | ≥ 955 | 263-287 | ≤ 80 |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 12) | (33-36) | ||

| N-38 | 1220-1250 | ≥ 899 | ≥ 955 | 287-310 | ≤ 80 |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 12) | (36-39) | ||

| N-40 | 1250-1280 | ≥ 923 | ≥ 955 | 302-326 | ≤ 80 |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 12) | (38-41) | ||

| N-42 | 1280-1320 | ≥ 923 | ≥ 955 | 318-342 | ≤ 80 |

| (12.8-13.2) | ( ≥ 11.6) | ( ≥ 12) | (40-43) | ||

| N-45 | 1320-1380 | ≥ 876 | ≥ 955 | 342-366 | ≤ 80 |

| (13.2-13.8) | ( ≥ 11.0) | ( ≥ 12) | (43-46) | ||

| N-48 | 1380-1420 | ≥ 836 | ≥ 876 | 366-390 | ≤ 80 |

| (13.8-14.2) | ( ≥ 10.5) | ( ≥ 11) | (46-49) | ||

| N-50 | 1400-1450 | ≥ 860 | ≥ 876 | 382-406 | ≤ 80 |

| (14.0-14.5) | ( ≥ 10.8) | ( ≥ 11) | (48-51) | ||

| 30M | 1080-1130 | ≥ 796 | ≥ 1114 | 223-247 | ≤ 100 |

| (10.8-11.3) | ( ≥ 10) | ( ≥ 14) | (28-31) | ||

| 33M | 1130-1180 | ≥ 836 | ≥ 1114 | 247-270 | ≤ 100 |

| (11.3-11.8) | ( ≥ 10.5) | ( ≥ 14) | (31-34) | ||

| 35M | 1170-1220 | ≥ 868 | ≥ 1114 | 263-287 | ≤ 100 |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 14) | (33-36) | ||

| 38M | 1220-1250 | ≥ 899 | ≥ 1114 | 287-310 | ≤ 100 |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 14) | (36-39) | ||

| 40M | 1250-1280 | ≥ 923 | ≥ 1114 | 302-326 | ≤ 100 |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 14) | (38-41) | ||

| 42M | 1280-1320 | ≥ 955 | ≥ 1114 | 318-342 | ≤ 100 |

| 12.8-13.2 | ( ≥ 12.0) | ( ≥ 14) | (40-43) | ||

| 45M | 1320-1380 | ≥ 995 | ≥ 1114 | 342-366 | ≤ 100 |

| (13.2-13.8) | ( ≥ 12.5) | ( ≥ 14) | (43-46) | ||

| 48M | 1360-1430 | ≥ 1027 | ≥ 1114 | 366-390 | ≤ 100 |

| (13.6-14.3) | ( ≥ 12.9) | ( ≥ 14) | (46-49) | ||

| 50M | 1400-1450 | ≥ 1033 | ≥ 1114 | 382-406 | ≤ 100 |

| (14.0-14.5) | ( ≥ 13.0) | ( ≥ 14) | (48-51) | ||

| 30H | 1080-1130 | ≥ 796 | ≥ 1353 | 223-247 | ≤ 120 |

| (10.8-11.3) | ( ≥ 10) | ( ≥ 17) | (28-31) | ||

| 33H | 1130-1180 | ≥ 836 | ≥ 1353 | 247-271 | ≤ 120 |

| (11.3-11.8) | ( ≥ 10.5) | ( ≥ 17) | (31-34) | ||

| 35H | 1170-1220 | ≥ 868 | ≥ 1353 | 263-287 | ≤ 120 |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 17) | (33-36) | ||

| 38H | 1220-1250 | ≥ 899 | ≥ 1353 | 287-310 | ≤ 120 |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 17) | (36-39) | ||

| 40H | 1250-1280 | ≥ 923 | ≥ 1353 | 302-326 | ≤ 120 |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 17) | (38-41) | ||

| 42H | 1280-1320 | ≥ 955 | ≥ 1353 | 318-342 | ≤ 120 |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 17) | (40-43) | ||

| 45H | 1320-1380 | ≥ 963 | ≥ 1353 | 342-366 | ≤ 120 |

| (13.2-13.8) | ( ≥ 12.1) | ( ≥ 17) | (43-46) | ||

| 48H | 1370-1430 | ≥ 995 | ≥ 1274 | 366-390 | ≤ 120 |

| (13.7-14.3) | ( ≥ 12.5) | ( ≥ 16) | (46-49) | ||

| 30SH | 1080-1130 | ≥ 804 | ≥ 1592 | 223-247 | ≤ 150 |

| (10.8-11.3) | ( ≥ 10.1) | ( ≥ 20) | (28-31) | ||

| 33SH | 1130-1170 | ≥ 844 | ≥ 1592 | 247-271 | ≤ 150 |

| (11.3-11.7) | ≥ 10.6 | ( ≥ 20) | (31-34) | ||

| 35SH | 1170-1220 | ≥ 876 | ≥ 1592 | 263-287 | ≤ 150 |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 20) | (33-36) | ||

| 38SH | 1220-1250 | ≥ 907 | ≥ 1592 | 287-310 | ≤ 150 |

| (12.2-12.5) | ( ≥ 11.4) | ( ≥ 20) | (36-39) | ||

| 40SH | 1250-1280 | ≥ 939 | ≥ 1592 | 302-326 | ≤ 150 |

| (12.5-12.8) | ( ≥ 11.8) | ( ≥ 20) | (38-41) | ||

| 42SH | 1280-1320 | ≥ 995 | ≥ 1592 | 318-342 | ≤ 150 |

| (12.8-13.2) | ( ≥ 12.5) | ( ≥ 20) | (40-43) | ||

| 45SH | 1320-1380 | ≥ 1003 | ≥ 1592 | 342-366 | ≤ 150 |

| (13.2-13.8) | ( ≥ 12.6) | ( ≥ 20) | (43-46) | ||

| 28UH | 1020-1080 | ≥ 764 | ≥ 1990 | 207-231 | ≤ 180 |

| (10.2-10.8) | ( ≥ 9.6) | ( ≥ 25) | (26-29) | ||

| 30UH | 1080-1130 | ≥ 812 | ≥ 1990 | 223-247 | ≤ 180 |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 25) | (28-31) | ||

| 33UH | 1130-1170 | ≥ 852 | ≥ 1990 | 247-271 | ≤ 180 |

| (11.3-11.7) | ( ≥ 10.7) | ( ≥ 25) | (31-34) | ||

| 35UH | 1180-1220 | ≥ 860 | ≥ 1990 | 263-287 | ≤ 180 |

| (11.8-12.2) | ( ≥ 10.8) | ( ≥ 25) | (33-36) | ||

| 38UH | 1220-1250 | ≥ 907 | ≥ 1990 | 287-310 | ≤ 180 |

| (12.2-12.5) | ( ≥ 11.4) | ( ≥ 25) | (36-39) | ||

| 30EH | 1080-1130 | ≥ 812 | ≥ 2388 | 223-247 | ≤ 200 |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 30) | (28-31) | ||

| 33EH | 1130-1170 | ≥ 812 | ≥ 2388 | 247-271 | ≤ 200 |

| (11.3-11.7) | ( ≥ 10.2) | ( ≥ 30) | (31-34) | ||

| 35EH | 1170-1220 | ≥ 876 | ≥ 2388 | 263-287 | ≤ 200 |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 30) | (33-36) | ||

| 30AH | 1080-1130 | ≥ 812 | ≥ 2785 | 223-247 | ≤ 240 |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 35) | (28-31) | ||

| 33AH | 1130-1170 | ≥ 812 | ≥ 2785 | 247-271 | ≤ 240 |

| (11.3-11.7) | ( ≥ 10.2) | ( ≥ 35) | 31-34 | ||

| NOTES: |

| The above-mentioned data of magnetic parameters and physical properties ars given at room temperature. |

| The maximum service temperature of magnet is changeable due to the ratio length and diameter and |

| Environmental factors. |

| Density: 7.4~7.6g/cm 3 ; α Br:-0.09~0.13%/ ℃, β Hcj: -0.50~0.80%/ ℃; Hv:600. |

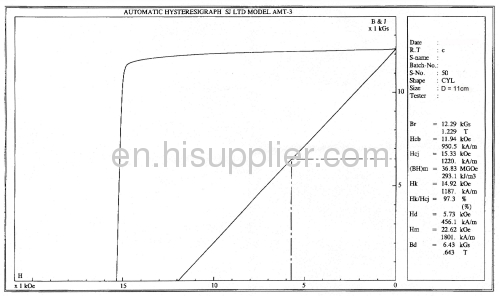

The demagnetized curve of N35 grade