Channel Nut With Plastic Wing

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1 container each month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Plastic wing type |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Material: | Steel |

| Brand Name: | OEM |

| Diameter: | Nut Width 19 mm |

| Length: | Nut Length 34.5 mm |

| Capacity: | Mpa Tensile loading |

| Material: | Carbon Steel & Stainless Steel |

| Design feature: | A plastic wing for inserting and holding the cuboid nut and embed-hang on the two edges of C channel steel structure |

| Function: | Realize secure & effective strut and fixing in channel steel structure and strut-connecting systems |

| Working principle: | Plastic wing realizes the similar function with the spring to fix the strut fittings with bolt or other fasteners |

| Surface treatment: | ZP & ZYP & HDG |

| Base materials: | Steel structure |

| Usage: | Used to install and fix pipes, conduit fittings, channel steel structures and channel steel section systems |

| Main production process: | Stamping machine and plastic injection machine |

| Installing advantage: | Easy-quick installing and allow to remove |

| Installation: | Installing in any place to insert it through the open side of the channel steel after pre-assembling the plastic wing |

| Production Capacity: | 1 container each month |

| Packing: | Packed in box to carton to pallet |

| Delivery Date: | as discussed |

Product Description

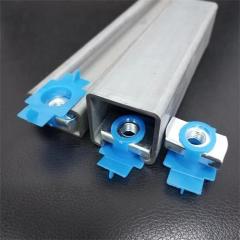

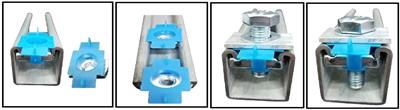

Channel nut with plastic wing is uniquely designed to pre-install a flexible plastic cover used to insert and hold the nut without common metal spring, the plastic cover achieve the similar function with the spring, not interfere and occupy the inner wall and the space of the channel steel.The sizes of plain channel nut remain unchanged. The two sides of plastic wing embrace the two edges of the channel and move freely to the any position of the channel structure.

The twin serrated grooves on one surface align it correctly with the two edges of channel steel and increase friction to fix it firmly. After the cuboid nut is inserted into the plastic cover, the height from the plastic wing to the top of the nut is exactly same as the edge height on both sides of the C channel steel and make the plastic wing just be embedded and hung on the edges to achieve strut channel accessories to be fixed in the place without additional operations.

In the middle of the plastic wing is designed as a hollow structure, vertically aligning with the threaded hole of the nut, and used to tighten the bolt to fix the fittings to channel steel syestmes. The channel spring nuts are available with different sizes according to different struts and support structures in different installation positions, achieve various installation and fixation purposes.

[Product Features]:

★ Pre-assemble a plastic wing used to insert and hold the cuboid nut & put the nut surface with twin grooves face the plastic wing.

★ Being suitable for the customized C channel steel size.

★ A cuboid nut by stamping process without spring.

★ Without spring is to support the bottom of channel steel and avoid the volume of the spring occupying the extra space.

★ Design dual grooves on one surface of the nut to enhance the friction touching two edges of channel steel.

★ No expanding function, having connecting and fixing use.

★ Pre-assemble the cuboid nut into plastic wing and insert from the opening side of channel steel by hand and put it in any position for use.

★ Fasten a bolt into a threaded hole in the center of the nut, easy and quick to install and remove.

★ Providing various surface treatments of the nut.

[Materials & Surface treatment]:

☞ Carton steel / Stainless Steel & ZP / ZYP / HDG / Dacromet

[Applications]:

▲ Fix and support C channel steel structure system.

▲ PV support structure system installing and fixing.

▲ Channel steel section connecting and combining engineering.

▲ Metal profiles system connect,support or suspend works.

▲ Installation works of shockproof support structure and hoisting.

[Installation Steps]:

① Pre-assemble a cuboid nut into a plastic wing and put the surface of twin grooves face plastic wing.

② Insert from the opening side by hand and move to the proper place for installing.

③ Pass a proper fastener through a guide hole in the fixture and screw it into the threaded hole in the middle of the nut.

④ To tighten until being fixed fully.

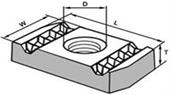

[Product size description of the cuboid nut]: (mm / inch)

Different cuboid nut use different plastic wing.

| Item Code | D-Thread Size | W-Nut Width | L-Nut Length | T-Nut Thickness |

| PSN14 | 1/4" | 19 mm | 34.5 mm | 6.0 mm |

| PSN516 | 5/16" | 19 mm | 34.5 mm | 6.0 / 8.0 mm |

| PSN38 | 3/8" | 19 mm | 34.5 mm | 8.0 / 9.2 mm |

| PSN12 | 1/2" | 19 mm | 34.5 mm | 9.2 / 11.8 mm |

| PSN58 | 5/8" | 30 mm | 34.5 mm | 11.0 mm |

| PSN34 | 3/4" | 30 mm | 34.5 mm | 11.0 mm |

| PSN78 | 7/8" | 30 mm | 34.5 mm | 11.0 mm |

| PSN06 | M6 | 19 mm | 34.5 mm | 6.0 mm |

| PSN08 | M8 | 19 mm | 34.5 mm | 6.0 / 8.0 mm |

| PSN10 | M10 | 19 mm | 34.5 mm | 8.0 / 9.2 mm |

| PSN12 | M12 | 19 mm | 34.5 mm | 9.2 / 11.8 mm |

| PSN14 | M14 | 30 mm | 34.5 mm | 11.0 mm |

| PSN16 | M16 | 30 mm | 34.5 mm | 11.0 mm |

| PSN18 | M18 | 30 mm | 34.5 mm | 11.0 mm |

| PSN20 | M20 | 30 mm | 34.5 mm | 11.0 mm |

**The special sizes and stainless steel of cuboid nuts are available.

** The various color of plastic wing are also available.