Shield Anchor Eye Bolt

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1 container each month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Folded Eye Bolt ZP |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Concrete Anchor |

| Material: | Steel |

| Brand Name: | OEM |

| Diameter: | Shield anchor body 12 mm ~ 32 mm |

| Length: | Folded eye bolt thread length 50 mm ~ 140 mm & special length |

| Capacity: | MPA |

| Material: | Carbon Steel |

| Surface treatment: | Zinc plating & Yellow passivated |

| Function: | Realize and generate expansion force |

| Design feature: | Pre-assemble shield anchor only with folded eye bolt |

| Usage: | Used to anchor & fix, hang, connect or pass the objects through eye bolt |

| Working principle: | Use a conical nut to expand shield anchor body when tightening the eye bolt |

| Base materials: | In the concrete,masonry,stone,brickwork substrate |

| Installation: | Pre-drill a hole in the substrate and to tighten by tool |

| Producing engineering: | Punching machine |

| Characteristic: | Quick and easy installation operation |

| Production Capacity: | 1 container each month |

| Packing: | Packed in box to carton to pallet |

| Delivery Date: | as discussed |

Product Description

Shield anchor eye bolt is sutiable for medium-heavy installation purpose. As one kind of heavy duty masonry anchor or expanding shield anchor, Three segment steel shields are made of carbon steel plate and produced by high speed automatic punching machine to ensure its high quality product performance. Steel shield anchor eyebolts are widely used to anchor & fix, hang,connect or pass the objects through the eye in various structure base materials.

Shield anchor with eyebolt is assembled folded eyebolt with shield anchor only. The eye bolt is folded and made by punching machine, which is different manufacturing process with forged steel eyebolt. When tightening eye head or the hex nut assembled and making a cone nut pull into and expand the expanding shield anchor to generate balanced expansion force in three directions in the hole wall drilled in the base materials to ensure security of installation and usage.

The steel three segment shields possess strong loading and tensile strength in the pre-drilled hole in the substrate, being also suitable for enlarged hole caused by drilling in weak base materials. By pulling down the cone nut, a strong spring ensure shield anchors return to normal assembled state when the improper expansion happened during the installation. By loosing the tightened fasteners, concrete shield anchor bolts are easily removed after being installed.

Product Features:

★ Pre-assembled with folded eye bolt & Din 934 hex nut & Din 125/9021 flat washer.

★ If being loose or fall scattered, could reassemble or replace a spring to be restored.

★ Generate three directions balanced expansion force provide optimal loading and ensure security of installing.

★ Used to anchor & fix, hang, connect or pass the objects through the eye

★ Being suitable for medium-heavy duty loading purpose and weak base materials.

Materials & Surface treatment:

☞ Carton steel & Zinc plating and Zinc plated and yellow passivated.

Base Materials: ☑ Concrete ☑ Masonry ☑ Brickwork ☑ Solid wall ☑ Stone

Applications:

● Special door industry,Wall panel.

● Installation of signs, handrails, railings, shelves and gates.

● Installation of grating and fence and heavy machinery installing.

● Pipe installation engineering / pipe support.

● Cables and tower racks, cable wire installation industry.

● Installation of starter bars for structural expansion and rectification works.

● Structural expansion and rectification works.

● Curtain walls, cladding and precast concrete components.

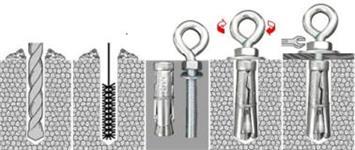

Installation Guide:

① Drill a hole in the base materials at right angle, diameter and depth.

② Clean the hole inside using a brush or air pump before installing.

③ Reorganize anchor body to the natural state and hammer the head to

insert it into the drilled hole until the flat washer tightly touch with

the substrate surface.

④ Turn the folded eye clockwise by proper tool and make body expand and fix fully for direct use purpose.

+Or, drive anchor body to pass through a guide hole in the fixture and insert into the drilled hole until the flat washer tightly touch with the fixture surface.

⑤ Fasten hex nut by tool until be fixed fully.

Product size description: (mm/inch)

| Item Code | Anchor Size | Anchor Length | Drill Dia. | Normal Eyebolt Size |

| 3PAE06 | M6 (1/4) | 45 | 12 | M6 X 50 |

| 3PAE08 | M8 (5/16) | 50 | 14 | M8 X 55 |

| 3PAE10 | M10 (3/8) | 60 | 16 | M10 X 70 |

| 3PAE12 | M12 (1/2) | 75 | 20 | M12 X 85 |

| 3PAE16 | M16 (5/8) | 115 | 25 | M16 X 125 |

| 3PAE20 | M20 (3/4) | 130 | 32 | M20 X 140 |

**The special eye bolt sizes are available.

** The folded, welded and forged eye bolt are available.

** Being available to assemble loose bolt, stud, projecting bolt, eye bolt and hook bolt.