.jpg)

Expanded Metal Lath

| Min. Order: | 2 Metric Ton |

|---|---|

| Payment Terms: | T/T L/C |

| Supply Ability: | 30 metric ton/week |

| Place of Origin: | Hebei |

Company Profile

| Location: | Beijing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stainless Steel Wire Meshes, Square Wire Meshes, Welded Wire Mesh, Aluminium Expanded Metal, Expanded Metals |

Product Detail

| Model No.: | SQ-02 |

|---|---|

| Means of Transport: | shipping |

| Type: | Expanded |

| Material: | Others |

| Brand Name: | Sanqiang |

| Production Capacity: | 30 metric ton/week |

| Packing: | as your request |

| Delivery Date: | 5-20 days |

Product Description

Expanded Metal lath

Expanded metal lath is also called pulled plate wire mesh. A rigid piece of metal that has been slit and drawn into an open mesh pattern in a single operation. It is stronger, lighter in weight and more rigid than the original base metal.

Materials:Steel Plate, Aluminum Plate, Stainless Steel Plate, Titanium Plate, Alum-Platinum Plate, Lead Plate, Nickel Plate, etc.

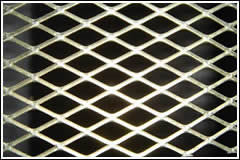

Conventional mesh is formed in a diamond pattern. It has other pattern of square, round, triangle, scale-like opening. Widely used in the agriculture, construction, medicine, filtering, paper-making, handicraft -making etc. We can supply expanded metal mesh in rolls or sheets of different sizes.

Expanded metal lath is also called pulled plate wire mesh. A rigid piece of metal that has been slit and drawn into an open mesh pattern in a single operation. It is stronger, lighter in weight and more rigid than the original base metal.

Materials:Steel Plate, Aluminum Plate, Stainless Steel Plate, Titanium Plate, Alum-Platinum Plate, Lead Plate, Nickel Plate, etc.

Conventional mesh is formed in a diamond pattern. It has other pattern of square, round, triangle, scale-like opening. Widely used in the agriculture, construction, medicine, filtering, paper-making, handicraft -making etc. We can supply expanded metal mesh in rolls or sheets of different sizes.

SWD:Short way of design measured from center of bond to center of bond.

LWD: Long way of design measured from center of bond to center of bond.

SWO: Short Way of Opening

LWO: Long Way of Opening

Strand: One side of expanded metal design.

LWD: Long way of design measured from center of bond to center of bond.

SWO: Short Way of Opening

LWO: Long Way of Opening

Strand: One side of expanded metal design.

Thickness: Thickness of the base metal

Bond: The solid intersection of two strands - Double the strand width.

Mesh: This is the nominal distance from the mid-point of one bond to the mid-point of the next bond measured across the SWD.

Regular expanded metal: Expanded metal mesh as it is produced off the expanded metal press with no secondary flattening operation. Material looks similar to a louvered design.

Flattened expanded metal : Expanded metal that has been cold-rolled after expansion, to provide a smooth, flat, and level sheet. The flattening process usually reduces the original gauge of the base metal.

Finishing : Limited finishes can be accomplished at manufacturing plants. This includes Electric-galvanized, hot-dipped galvanized, spray-painted.

Coil: Expanded metal that is produced to a specific width and then wound on a core.

Sheet: Expanded metal that is produced to a specific width and length.

Bond: The solid intersection of two strands - Double the strand width.

Mesh: This is the nominal distance from the mid-point of one bond to the mid-point of the next bond measured across the SWD.

Regular expanded metal: Expanded metal mesh as it is produced off the expanded metal press with no secondary flattening operation. Material looks similar to a louvered design.

Flattened expanded metal : Expanded metal that has been cold-rolled after expansion, to provide a smooth, flat, and level sheet. The flattening process usually reduces the original gauge of the base metal.

Finishing : Limited finishes can be accomplished at manufacturing plants. This includes Electric-galvanized, hot-dipped galvanized, spray-painted.

Coil: Expanded metal that is produced to a specific width and then wound on a core.

Sheet: Expanded metal that is produced to a specific width and length.