.jpg)

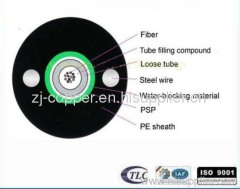

Unitube Light-armored Cable

2.0 RMB

| Min. Order: | 2000 m |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GYXTW |

|---|---|

| Brand Name: | NECERO |

| Certificate: | ISO 9001:2000 |

| Delivery Date: | 10 days |

Product Description

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. The tube is wrapped with a layer of PSP longitudinally. Between the PSP and the loose tube water-blocking material is applied to keep the cable compact and watertight. Two parallel steel wires are placed at the two sides of the steel tape. The cable is completed with a polyethylene (PE) sheath.

· Good mechanical and temperature performance

· High strength loose tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· Crush resistance and flexibility

· PSP enhancing moisture-proof

· Two parallel steel wires ensure tensile strength

· Small diameter, light weight and friendly installation

· Long delivery length

· Characteristics

· Good mechanical and temperature performance

· High strength loose tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· Crush resistance and flexibility

· PSP enhancing moisture-proof

· Two parallel steel wires ensure tensile strength

· Small diameter, light weight and friendly installation

· Long delivery length

· Standards

GYXTW YD/T 769-2003