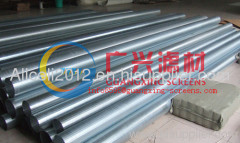

wedge wire well screen for well drilling

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | gx21 |

|---|---|

| Means of Transport: | Ocean |

| Structure: | Filtering Machine |

| Material: | Others |

| Function: | Water Filter |

| Brand Name: | guangxing |

| stainless steel screen: | well screen |

| Production Capacity: | 100 |

| Packing: | wooden |

| Delivery Date: | 15days |

Product Description

Our company is a professional mnufacturer of well screen.

I'm Joanna sun from hengshui China guangxing screen Co.ltd

The continuous-slot screen is widely used throughout the world for water, oil, and gas

wells, and is the dominant screen type used in the water well industry. It is made by

winding rolled wire, triangular in cross section, around a circular array of longitudinal rods.

The wire is attached to the rods by welding. Welded screens are commonly fabricated

from stainless steel.

Slot openings are manufactured by spacing successive turns of the outer wire to produce

the desired slot size. Slot openings have been designated by numbers which correspond

to the width of the openings in thousandths of an inch. A No. 10 slot screen, for example,

is an opening of 0.010 inch.

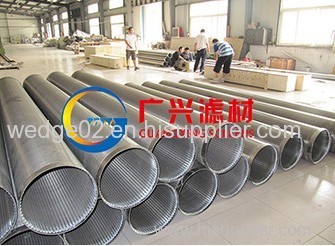

Continuous-slot screens provide more intake area per unit area of screen surface than any

other type. This type of screen has maximum open area. For best well efficiency, the

percentage of open area in a screen should be the same as, or great than, the average

porosity of the aquifer material. Water flows more freely through a screen with a large

intake area compare to one with limited open area. The entrance velocity is low, therefore

head loss for the screen is at a minimum, thus minimizing drawdown in the well.

Well Screen | ||

Specification (Profile wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 | |

Specification (support rods): | Width(mm): 2.30 3.00 3.30 3.70 | |

Note: other wires and rods available upon request | ||

Slot size | 0.10, 0.15, 0.20, 0.25, 0.30^ 6.00mm also achieved upon request. | |

Material: | Low carton, low carton galvanized steel (LCG), stainless steel (304,316 etc.) | |

Length | 2.9 meters,3 meters,5.8 meters,6 meters. | |

Diameter | 1 1/2",2",2 1/2",3",3 1/2",4",6",7",8",9 5/8",10",12",133/8",14",16" | |

Screen end | Plain beveled ends for butt welding or threaded | |

Other sizes available on request .Deep well construction specifications available on question. Well depths :100 m, 200 m, 350 m & 600 m. | ||

Advantage

| Reduce energy consumption and increase water flow. Reduce erosion of entry surfaces and increase well life. Allow a uniform and efficient well development. Reduce significantly potential pump damage and subsequent maintenance costs. | |