The Copper Rod Continuous Casting

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 50000 Piece/Pieces / Month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Oil Spray Gun / Spray Gun, Hand Wheel / CNC Hand Wheel, Cheap Ball Screw / Slotted Shoulder Screw, Air Spring / Air Power Tech, High Quality Metal Wheel Chock |

Product Detail

| Model No.: | As Per Your Requirements |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Aosite |

| Place of Origin: | Shaanxi, China (Mainland) |

| Brand Name: | Aosite |

| Model Number: | As Your Request |

| Engine Type: | Gasoline |

| Type: | Piston |

| OEM: | Accepted |

| Sample: | For Free |

| Certificate: | ISO&SGS |

| Style: | Public |

| Production Capacity: | 50000 Piece/Pieces / Month |

| Packing: | To be packed in wooden cases |

| Delivery Date: | One month after you place an order |

Product Description

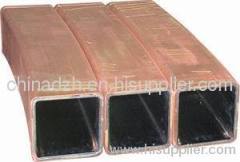

The Copper Rod Continuous Casting

Equipment application

1.The copper rod continuous casting and rolling line can be equipped with differentkinds of melting furnaces according to various raw materials (copper cathode orcopper scrap of above 94% Cu content).

2.The copper rod continuous casting and rolling machine can produce ETP and FRHC with dia.8mm.

3.The copper rod continuous casting and rolling machine is designed to produce φ8mm low oxygenand bright copper rods by means of continuous casting and rolling.

Equipment feature

1. Crystallizing wheel is in type of"H", and cooling on every side. External and side cooling is divided into 4sections, and internal cooling is divided into six sections. Each section'ssupplying for water is separately adjusted, and its pressure can be shown in thepressure gauge so that make ingots even cooled, grain refined and high technological adaptability.

2. The tension of steelbelt is pneumatic control. Tension can be easily adjusted by adjusting the airpressure. The tension of steel belt is constant after it is set which makes forthe stable die chamber.

3. It is withthe unique rolling method combining 2-high mould with 3-high mould, which can increase the deformation of ingot in the high-temperature stage.

4. The production line isprovided with the function of continuous reverting for rod surface and fastcooling to assure the light and temperature of finished rod can becontrolled.

5. By using of optimum design for casting machine, lower the approach span height, which makes thefinished ingot as high as rolling center. What's more, it lowers the installbase level of ingot pulling machine, rolling shear, straightener & edgeshaver and rolling mill to zero point. It will reduce foundation cost, as wellas favor the workers' operational safety.

6. With perfect outlook, lower noise andvibration.

7. The transmission system is in type of DC motor fully-digital speed adjusting.

8. Easy to disassemble and assemble.

9. High efficiency and quality of production but low dissipation energy.

Equipment composition

The copper rod continuous casting and rolling line is made up by reverberatory furnace ortilting type furnace (when copper scraps are as the raw materials), shaftfurnace and holding furnace are provided when copper cathode are used, 5-wheelcasting machine, traction engine, scrolling shear, ingot picker, oil hydraulicshear, straightener and edge shaver, cast bar brushing machine, rolling mill,Rod cooling and surface treatment unit, take-up device electric controlsystem,etc.

We believe that we can be your ideal partner !

Your friendly inquiry would be highly appreciated !