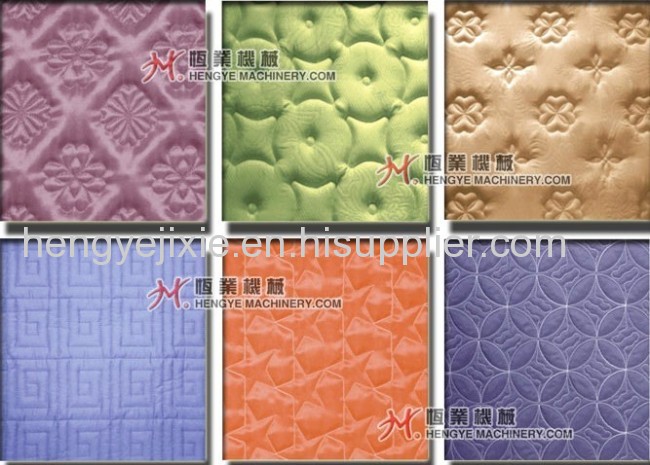

bed cover quilting machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 5 sets a month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Multi Needle Quilting Machine, Multi Functional Quilting Machine, China Computerized Chain Stitch Multi-needle Quilting Machine Manufacturer |

Product Detail

| Model No.: | HY-94-2A, HY-94-3A, HY-128-3A |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Hengye |

| Space between needle row: | 76.2, 152.4 |

| Space between needle: | 25.4 |

| X-axis movement displacement: | 305 |

| Thickness of quilting: | ≤25 |

| Stitch length: | 2~5 |

| Model of needle: | 16#, 19# |

| Production Capacity: | 5 sets a month |

| Packing: | Exporting standard packing |

| Delivery Date: | 25-30 days after received deposite |

Product Description

| Parameter Unit ( mm ) | HY-94-2A | HY-94-3A | HY-128-3A |

| Dimension(L×W×H) | 4500×1120×1750 | 4500×1160×1750 | 5350×1160×1800 |

| Quilting width | 2450 | 2450 | 3300 |

| Quantity of needle bar | 2 | 3 | 3 |

| Space between needle rows | 76.2 | 76.2, 152.4 | 76.2, 152.4 |

| Space between needles | 25.4 | 25.4 | 25.4 |

| X-axis movement displacement | 305 | 305 | 305 |

| Thickness of quilting | ≤25 | ≤25 | ≤25 |

| Stitch length | 2~5 | 2~5 | 2~5 |

| Speed of production(m/h) | 20-100 | 20-100 | 20-90 |

| Model of needle | 16#, 19# | 16#, 19# | 16#, 19# |

| Speed of main shaft(RPM): | 550~600 | 550~600 | 550~650 |

| Total power required | 3.5KW | 3.5KW | 4.5KW |

| Votage | 380V/50HZ 220V/60HZ | 380V/50HZ 220V/60HZ | 380V/50HZ 220V/60HZ |

| Gross weight | 2300kg | 2800kg | 4200kg |

| Certification: | CE Certificate | ||

More detail about our machine:

1.Needle bar and press plate are connected by cam-free double-swinging device, which is with high precision and durable. This structure can avoid lubrication and dirty material effectively.

2.High rigidity machine body and structure can make the machine running faster and more stable.

3.Adopting the new structure of press plate's adjusting makes the machine much simple.

4.Multi-span independent pattern (360°and 180°patterns are available)

5.Advanced and practical up thread-break detection unit.

6.Computerized automatic needle-lifting speed adjustment

7.New generation of CNC system, advanced machine structure, high precision quilting, dispense with too much parameter adjustment or pattern modification during quilting

8.Easy preparation of CAD drawing extremely precise

9.Different patterns in each line can be quilted on 3.2m fabric and patterns can strongly combine

10.Able to quilt simple embroidery patterns

11.Fault detecting and indication enabling fast fault correction and return operattion.