Asia computerized chain stitch multi-needle quilting machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 5 Sets a month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Multi Needle Quilting Machine, Multi Functional Quilting Machine, China Computerized Chain Stitch Multi-needle Quilting Machine Manufacturer |

Product Detail

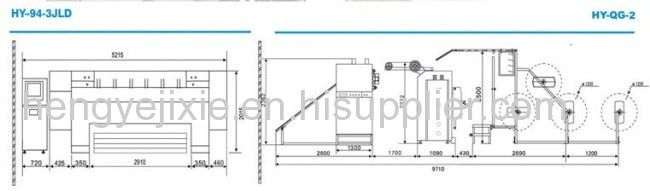

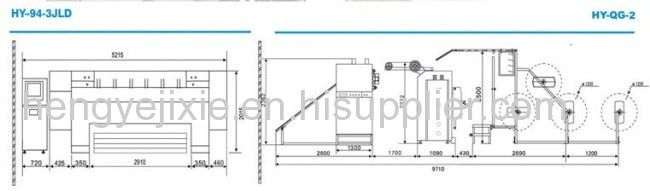

| Model No.: | HY-94-3JLD |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Hengye |

| Dimension(L×W×H): | 4715×1200×2015 |

| Production Capacity: | 5 Sets a month |

| Packing: | Exported standard packing |

| Delivery Date: | 25-30 days after received deposit |

Product Description

Parameter

The structure of the machine:

The function of the machine:

1.Needle bar and press plate are controlled by a double- swinging device without cam avoiding lubrication and dirtying of material

2.Multi-span and independent patterns(360°and 180°patterns are available)

3.Automatic stop motion control in case the top thread or the bottom thread breaks,automatic needle-lifting and CNC speed adjustment

4.CE Certificate

5.No need to adjust the press plate' s position when the thickness of quilting material varies

6.Outstanding features such as high rigidity, high running speed, low vibration and noise

7.CNC precision control system

8.Easy preparation of CAD drawings extremely precise

9.Strong functions of pattern-combining and multi-span quilting to enable you to quilt different patterns in each row in the mattresses of different sizes

10.Fault detection function for ease of determining the running state of the machine at any given time

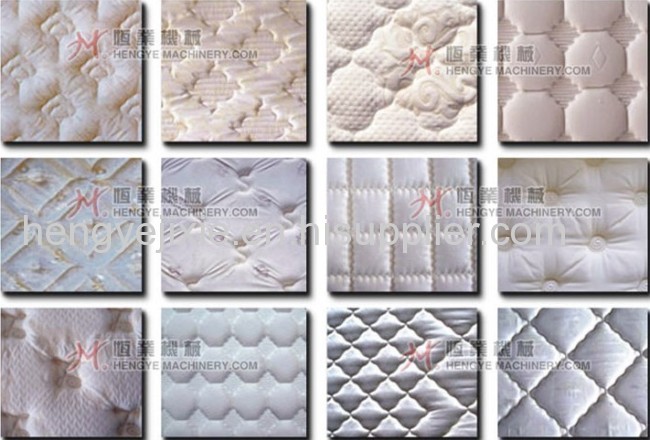

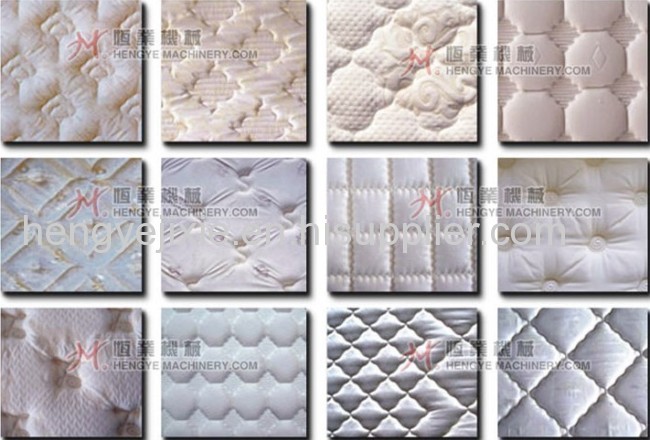

The pattern we make:

| HY-94-3JLD | Parameter Unit ( mm ) |

| Dimension(L×W×H) | 4715×1200×2015 |

| Quilting width | 2450 |

| Space between needle rows | 50.8,76.2,127(5") 76.2,76.2,152.4(6") |

| Space between needles | 25.4 |

| X-axis movement displacement | 410 |

| Thickness of quilting | ≤50(for all patterns) |

| Stitch length | 3~8 |

| Speed of operation | 45~180(m/hour) |

| Model of needle | 24/180 23/160 22/140 21/130 |

| Quilting speed | 650~930(RPM) |

| Total power required | 5KW |

| Votage | 380V/50HZ 220V/60HZ |

| Gross weight | 4000kg |

| Certification: | CE Certificate |

The structure of the machine:

The function of the machine:

1.Needle bar and press plate are controlled by a double- swinging device without cam avoiding lubrication and dirtying of material

2.Multi-span and independent patterns(360°and 180°patterns are available)

3.Automatic stop motion control in case the top thread or the bottom thread breaks,automatic needle-lifting and CNC speed adjustment

4.CE Certificate

5.No need to adjust the press plate' s position when the thickness of quilting material varies

6.Outstanding features such as high rigidity, high running speed, low vibration and noise

7.CNC precision control system

8.Easy preparation of CAD drawings extremely precise

9.Strong functions of pattern-combining and multi-span quilting to enable you to quilt different patterns in each row in the mattresses of different sizes

10.Fault detection function for ease of determining the running state of the machine at any given time

The pattern we make: