.jpg)

High Temperature Oven

5000.0 RMB

| Min. Order: | 1 pcs |

|---|---|

| Payment Terms: | Consultations |

| Supply Ability: | 5000pcs |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Guangzhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | RC-XHT125 |

|---|---|

| Means of Transport: | air freight |

| Specification: | Temperature fluctuation is les |

| Function: | Heat,degassing, recovery |

| Export Area: | Europe, North America, Asia |

| Production Capacity: | 5000pcs |

| Packing: | waterproof wooden cases |

| Delivery Date: | 3d |

Product Description

High Temperature Oven :

- Applications: cooking, degassing, pre-heating, recovery, high temperature sterilization, pyrolyse, tests,...

- Temperature range: from 20°C over ambient temperature up to 500°C. Five sizes: from 75 litres to 686 liters.

- Several options and accessories to adapt the oven to your needs.

- Volumes : 75, 125, 343, 490, 686 litres.

Performances :

Temperature up to 500°C. Temperature fluctuation is less than ± 0,2 °C . Temperature spatial variation is less than ± 2,5°C at 200°C (measure done with 9 probes inside the work chamber).

Temperature up to 500°C. Temperature fluctuation is less than ± 0,2 °C . Temperature spatial variation is less than ± 2,5°C at 200°C (measure done with 9 probes inside the work chamber).

Construction :

5 sizes of ovens are available from 75 to 686 liters. The inner casing is made of corrosion and heating resistant stainless steel, type 321. The outer case is made of sheet steel, finished in a tough stoved epoxy paint. (colour light grey RAL 7035) No contact between inner and outer case and an optimised insulation minimise heat transfer to the ambient air and heat dissipation. Walls and door are insulated with glass fibre. The insulation is 150 mm thick, this ensures efficicent operation, low external temperatures and excellent thermal stability. A special gasket provides a good seal between the door and the oven body, aiding insulation. The insulation as well as the gasket are asbestos-free. The door is hinged on the right hand side and closed with a robust 2 points fastener.

5 sizes of ovens are available from 75 to 686 liters. The inner casing is made of corrosion and heating resistant stainless steel, type 321. The outer case is made of sheet steel, finished in a tough stoved epoxy paint. (colour light grey RAL 7035) No contact between inner and outer case and an optimised insulation minimise heat transfer to the ambient air and heat dissipation. Walls and door are insulated with glass fibre. The insulation is 150 mm thick, this ensures efficicent operation, low external temperatures and excellent thermal stability. A special gasket provides a good seal between the door and the oven body, aiding insulation. The insulation as well as the gasket are asbestos-free. The door is hinged on the right hand side and closed with a robust 2 points fastener.

Heating :

The tubular heating elements are sheathed and made of stainless steel. They are ideally placed in the air blow. No-wear switching (solid state relay) is used for activating and deactivating the heating elements.

The tubular heating elements are sheathed and made of stainless steel. They are ideally placed in the air blow. No-wear switching (solid state relay) is used for activating and deactivating the heating elements.

Internal fan for air circulation :

All ovens are fan circulated. The air flow speeds up the heating time and also evens the temperature distribution within the oven. The centrifugal blower is located at the top of the oven, shielded from the workspace by a stainless steel baffle. Air is drawn into the fan from the top in the centre of the oven and passes over the temperature sensor and the sheathed heater elements. The heated air is distributed in the bottom of the oven through the whole width and then re-circulated by the fan.

All ovens are fan circulated. The air flow speeds up the heating time and also evens the temperature distribution within the oven. The centrifugal blower is located at the top of the oven, shielded from the workspace by a stainless steel baffle. Air is drawn into the fan from the top in the centre of the oven and passes over the temperature sensor and the sheathed heater elements. The heated air is distributed in the bottom of the oven through the whole width and then re-circulated by the fan.

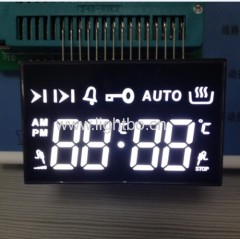

Temperature control and safety :

Temperature sensor is a J thermocouple. Temperature is controlled by a precise microprocessor-based controller that provides a high accuracy and prevents the set temperature from being exceeded. The controller digitally displays continuously the set and actual values of temperature. An independent second electronic controller, with a second thermocouple, has an adjustable upper limit, giving a class 2 protection.

Temperature sensor is a J thermocouple. Temperature is controlled by a precise microprocessor-based controller that provides a high accuracy and prevents the set temperature from being exceeded. The controller digitally displays continuously the set and actual values of temperature. An independent second electronic controller, with a second thermocouple, has an adjustable upper limit, giving a class 2 protection.

Exhaust air, fresh air supply :

Through access vent, fresh air is provided and pre-heated before entering the chamber. A 40 or 60 mm diameter exhaust vent (depending on the model) is provided with an adjustable valve to control the exhaust air flow.

Through access vent, fresh air is provided and pre-heated before entering the chamber. A 40 or 60 mm diameter exhaust vent (depending on the model) is provided with an adjustable valve to control the exhaust air flow.

Equipment :

Fixed shelving for convenient loading / unloading. 1 shelf is supplied for XHT075 and 2 for the other models. Additional shelves are available. A 20 mm diameter access port with fiber cork is fitted as standard in the left hand wall of the oven

Fixed shelving for convenient loading / unloading. 1 shelf is supplied for XHT075 and 2 for the other models. Additional shelves are available. A 20 mm diameter access port with fiber cork is fitted as standard in the left hand wall of the oven

|

Model

|

Internal dimensions (WxDxH)

|

External dimensions (WxDxH)

|

|

XHT075

|

500 x 500 x 300

|

848 x 877 x 924

|

|

XHT125

|

500 x 500 x 500

|

850 x 880 x 1125

|

|

XHT343

|

700 x 700 x 700

|

1025 x 1150 x 1430

|

|

XHT490

|

700 x 700 x 1000

|

1025 x 1150 x 1730

|

|

XHT686

|

700 x 700 x 1400

|

1025 x 1150 x 2130

|