.jpg)

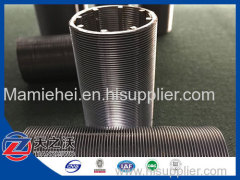

Reverse rolled slotted wedge wire screens

| Place of Origin: | Hebei |

|---|

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HX |

|---|---|

| Brand Name: | Haixing |

| Specification: | custom designed |

| Function: | self-cleaning, filtering |

| Certificate: | ISO 9001:2000 |

Product Description

The revolutionary reverse rolled wedge wire straining element is extremely rugged and more clog-resistant than conventional strainer elements that use perforated plate or wire mesh screens.

This proven state-of-the-art straining media is fabricated by wrapping vertical rods with wedge shaped profile wire. Each intersection of rod and wire is welded to produce an extremely rugged one-piece element. This forms a continuous slot that allows only two point contact with debris particles to reduce clogging.

The reverse rolled slotted wedge wire screens provide continuous debris removal from fluid piping systems that demand full time uninterrupted flow and can operate through a wide range of positive operating pressure and solids loading with effective debris removal and back washing across the entire pressure range.

Applications: Chemical generally, water applications including drinking and photographic use as well river water, sea water, beverage and food products, bright quenching and cutting fluids, plating solutions, oils and distillates, industrial liquids of every kind.

Applications: Chemical generally, water applications including drinking and photographic use as well river water, sea water, beverage and food products, bright quenching and cutting fluids, plating solutions, oils and distillates, industrial liquids of every kind.

Advantages:

Maximum effective flow area and maximum operating efficiency are maintained throughout service life.

Maintenance costs are reduced drastically due to reduced clogging and stapling of fibrous material.

Long-lived straining element provides reduced operating costs over entire service life.

Rigid element prevents flexing which can cause premature element failure.

Efficient, effective debris collection at media/screen interface.

We can also make manufacture according to your detail specifications and we assure that we will give you the best services.

If you are interested in our products please feel free to contact us and your inquiry will meet with our careful attention.

If you are interested in our products please feel free to contact us and your inquiry will meet with our careful attention.

.jpg)

.jpg)

.jpg)