.jpg)

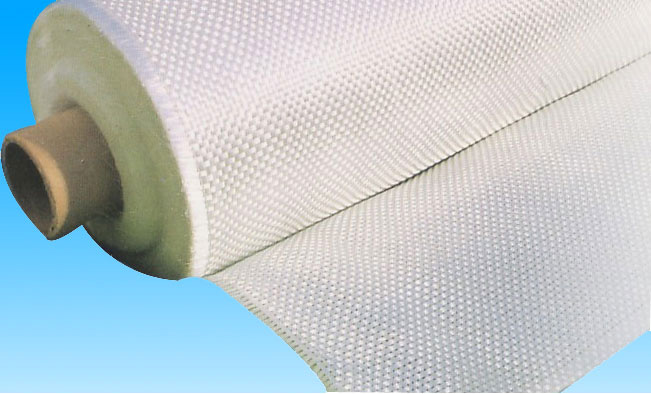

Woven Roving

| Place of Origin: | Jiangsu |

|---|

Company Profile

| Location: | Yangzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Description

Product Introduction

W1-A E-glass Woven Rovings are composed of direct rovings woven into a fabric. The input rovings are designed to give rapid wet-out and excellent laminate properties. The construction gives bi-directional (0°/90°) reinforcement and the strength of continuous filaments. The type of construction confers to the fabric an excellent dimensional stability during handling. W1-A is ideal for hand and machine production of boats, containers, aircraft and automotive parts, home furnishings, sports equipment, corrosion-resistant tanks, translucent panels, and other parts with large areas.

Product Description

All W1-A Woven Rovings are manufactured to meet ISO 9001 standards. These products have obtained the quality certification of Norway Boat code. W1-A is designed to be compatible with most resins and is widely used in a multitude of applications.

Packaging

W1-A Woven Roving is wound into a roll on a cardboard inner tube with an inside diameter of 8cm (3.1"). All densities are 23cm (9") in diameter. Each roll is wrapped with a plastic bag and placed in a cardboard box. 12 or 16 boxes are placed horizontally on a pallet, which is stretch wrapped.

Storage

Unless otherwise specified, it is recommended to store glass fiber products in a cool, dry area. Temperature should not exceed 35°C (95°F) and the relative humidity should be kept below 75%. Glass roving products must remain in packaging material until just prior to their use. If these conditions are respected, the glass fiber product should not undergo significant changes when stored for extended periods of time.

Stacking

To ensure safety and avoid damage to the product, skids should not be stacked more than two high.

Customer Benefits

W1-A E-glass Woven Rovings are composed of direct rovings woven into a fabric. The input rovings are designed to give rapid wet-out and excellent laminate properties. The construction gives bi-directional (0°/90°) reinforcement and the strength of continuous filaments. The type of construction confers to the fabric an excellent dimensional stability during handling. W1-A is ideal for hand and machine production of boats, containers, aircraft and automotive parts, home furnishings, sports equipment, corrosion-resistant tanks, translucent panels, and other parts with large areas.

Product Description

All W1-A Woven Rovings are manufactured to meet ISO 9001 standards. These products have obtained the quality certification of Norway Boat code. W1-A is designed to be compatible with most resins and is widely used in a multitude of applications.

Packaging

W1-A Woven Roving is wound into a roll on a cardboard inner tube with an inside diameter of 8cm (3.1"). All densities are 23cm (9") in diameter. Each roll is wrapped with a plastic bag and placed in a cardboard box. 12 or 16 boxes are placed horizontally on a pallet, which is stretch wrapped.

Storage

Unless otherwise specified, it is recommended to store glass fiber products in a cool, dry area. Temperature should not exceed 35°C (95°F) and the relative humidity should be kept below 75%. Glass roving products must remain in packaging material until just prior to their use. If these conditions are respected, the glass fiber product should not undergo significant changes when stored for extended periods of time.

Stacking

To ensure safety and avoid damage to the product, skids should not be stacked more than two high.

Customer Benefits

- Advantages in reducing costs and contributing to end-product quality

- Uniform weight and construction minimize the potential for air entrapment and weak areas in the laminate. This helps produce stronger, smoother parts

- Drapes well, lays easily on radii and corners, and conforms easily to intricate shapes and patterns

- Reduce fabrication time

- Wets out faster and more evenly to accelerate rolling and brushing

Product DataID Number Filament Diameter (Microns) Density (g/m², Oz/ydm²) Linear Density (TEX/Yield) Construction (ends/inch) Thickness (mm/inch) Weave Structure Warp Weft Warp (0°) Weft (90°) W1-180-A 17 600/18 1150/435 1150/435 6.6 6.6 0.55/0.022 Plain W1-240-A 17 800/24 2300/216 2300/216 4.6 4.0 0.85/0.033 Plain ID Number Sizing Type % Organic solid Standard Widths (mm/in) Length/roll (m/feet) Roll Weight (kg/lb) Compatible Resin W1-180-A Silane 0.55 ± 0.2 965/38

1270/50

1520/6066/216

66/216

66/21640/88

50/110

60/132- Polyester

- VinylesterW1-240-A Silane 0.55 ± 0.2 1000/39

1270/50

1520/6050/164

50/164

50/16440/88

50/110

60/132- Polyester

- VinylesterTypical Polyester Laminate Properties

* Reference data only, not for technical specifications. Glass content: 58.7%. Unsaturated Polyester for general purpose.Property Average Value Test Method Tensile Strength (MPa) 286 GB/T1447-1983 Flexural Strength (MPa) 441 GB/T1449-1983 Tensile Modulus (GPa) 18.8 GB/T1447-1983 Flexural Modulus (GPa) 20.4 GB/T1449-1983 Elongation (%) 2.0 GB/T1447-1983

.jpg)

.gif)