Pilot operated pressure reducing Valve

10.0~100.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 20000pc/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

| Main Products: | Hydraulic Orbit Motor, Piston Hydraulic Motors, Rexroth Pump Part, A10V Pumps, Auto Hoist Power Units |

Product Detail

| Model No.: | DR...30B/ |

|---|---|

| Power: | Solenoid |

| Standard or Nonstandard: | Standard |

| Pressure: | High Pressure |

| Structure: | Pressure Reducing |

| Material: | Casting |

| Temperature of Media: | Others |

| Media: | Oil |

| Brand Name: | Power |

| Production Capacity: | 20000pc/month |

| Packing: | carton |

| Delivery Date: | 2 weeks |

Product Description

Features:

-For subplate mounting

-For threaded connections

-For cartridge connection

-4 adjustment elements:

. Rotary knob.

. Sleeve with hexagon and protective cap,

. Lockable rotary knob with scale

. Rotary knob with scale

-4 pressure settings

-optional check valve (only for valve for subplate mounting)

Functional description, section

Pressure valves type DR are pilot operated pressure reducing valves, which are controlled from the secondary circuit. They basically consist of main valve (1) with main spool insert (3) and pilot valve (2) with pressure adjustment element(9).

At rest, the valves are open, fluid can freely pass from port B to port A via the main spoo1(3).

Pressure present in port A acts upon the bottom side of the main spool(3). At the same time there is pressure acting on the poppet (6)in the pilot valve (2) via the orifice (4) on the spring-loaded side of the main spool (3) and via the port (5). Same it is acting on the poppet (6) via the orifice (7), control line (8) and orifice (10). According to setting of spring (11), pressure builds up in front of the poppet (6), in port (5) and in spring chamber (12), holding the control spool (3) in the open position. Fluid can freely flow from port B to port A via main spool (3), until the pressure in port A exceeds the value set at spring (11) and opens the poppet (6). The control spool (3) moves to closing position.

The desired reduced pressure is achieved, when a balance between the pressure in port A and the pressure set at spring (11) is reached.

Pilot oil drain from spring chamber (12) to tank takes place externally via line (15).

Free return flow from port A to B can be achieved by installing an optional check valve (14).

A pressure gauge connection (17) allows the reduced pressure in port A to be monitored.

Section:

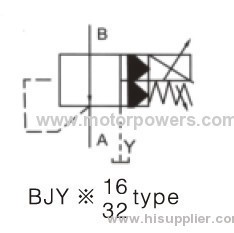

Symbol:

Ordering codes:

Technical data:

Size | 8 | 10 | 15 | 20 | 25 | 30 | ||

Flow (L/min) | Subplate mounting | - | 80 | - | 200 | - | 300 | |

Threaded connection | 80 | 80 | 200 | 200 | 300 | 300 | ||

Max. operating pressure(inlet) Mpa | To 10 or to 31.5 | |||||||

Inter pressure Mpa | To 31.5 | |||||||

outlet pressure Mpa | 0.3~31.5 | 1~31.5 | ||||||

Back pressure Mpa | To 31.5 | |||||||

Pressure Fluid | Mineral oil or Phospate ester | |||||||

Viscosity range mm²/s | 10~800 | |||||||

Temperature range ℃ | -30~+80 | |||||||

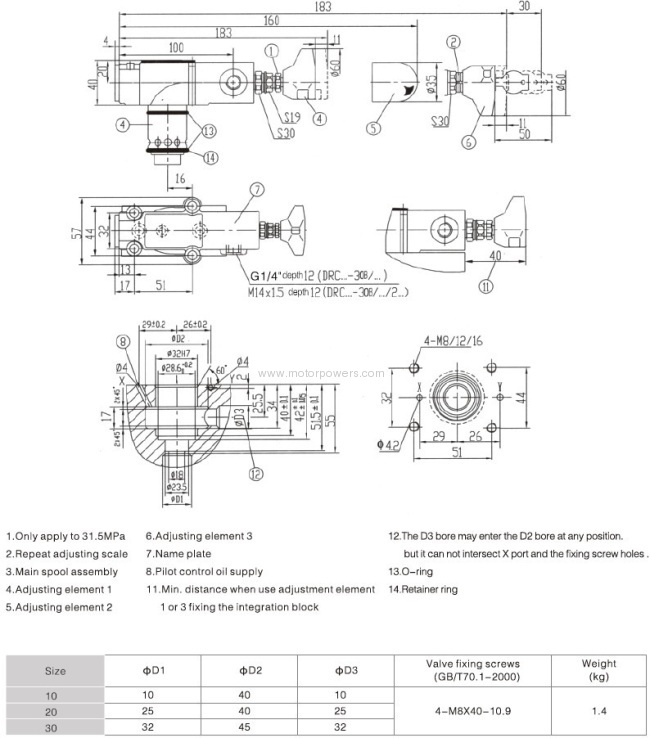

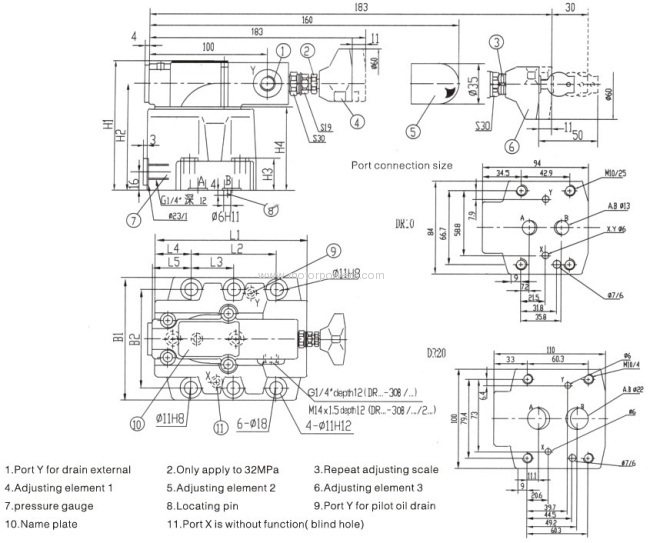

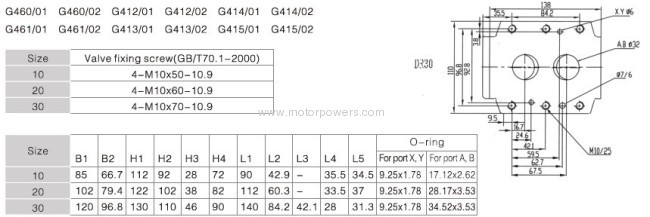

Unit dimensions (dmensions in mm)

Subplate mounting:

Port size

Threaded connnection

Cartridge connection