Pressure reducing valve direct operated of sandwich plate

10.0~100.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 20000pc/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

| Main Products: | Hydraulic Orbit Motor, Piston Hydraulic Motors, Rexroth Pump Part, A10V Pumps, Auto Hoist Power Units |

Product Detail

| Model No.: | ZDR6DA...30B/ |

|---|---|

| Power: | Solenoid |

| Standard or Nonstandard: | Standard |

| Pressure: | High Pressure |

| Structure: | Pressure Reducing |

| Material: | Stainless Steel |

| Temperature of Media: | High Temperature |

| Media: | Oil |

| Brand Name: | Power |

| Weight: | 1.2kg |

| Back pressure: | 6Mpa |

| Secondary pressure: | 21Mpa |

| Production Capacity: | 20000pc/month |

| Packing: | carton |

| Delivery Date: | 2 weeks |

Product Description

Features of Pressure reducing valve direct operated of sandwich plate:

-Sandwich plate design

-4 pressure ratings

-3 adjustment elements:

. Rotary knob

. Sleeve with hexagon and protective cap

. Lockable rotary knob with scale

- Pressure reduction in ports A, P, B

-Check valve, optional

Functional description of Pressure reducing valve direct operated of sandwich plate

Pressure reducing valves type ZDR 6 D_ are 3-way direct operated pressure reducing valves of sandwich plate design with a pressure relief function on the secondary side. It is used to reduce the system pressure. The pressure reducing valve basically consists of the housing (1), the control spool (2), a compression spring (3) and the adjustment element (4) as well as with an optional check valve.

The secondary pressure is set by the pressure adjustment element (4).

Model " A"

At rest, the valve is normally open, and fluid can flow unhindered from port A to port A1. The pressure in port A1 is at the same time via the control line (5) present at the spool area opposite to the compression spring (3). When the pressure in port A1 exceeds the pressure level set at the compression spring (3) the control spool (2) moves into the control position against the compression spring (3) and holds the set pressure in port A1 constant. The control pressure and pilot oil are taken from port A1 via control line (5).

If the pressure in port A1 rises still further due to external forces, the control spool (2) is moved still further towards the compression spring. This causes a flow path to be opened at port A through line (6) on the control spool (2) to tank. Sufficient fluid then flows to tank to prevent any further rise in pressure. The spring chamber (7) is always drained to tank externally via drilling (6) to port T (Y).

A pressure gauge connection (8) permits the secondary pressure at the valve to be monitored. It is only possible to fit a check valve for free flow in ports A1 to A in version "DA".

Models "DP" and "DB"

In model "DP", the pressure is reduced in port P1. The control pressure and the pilot oil is taken internally from port P1. In model "DB", the pressure in port P1 is reduced, and the pilot oil taken from port B.

Attention!

In model DB, it must be ensured, that the pressure in port B is not higher than the set pressure when the directional valve is in position P to A. Otherwise, pressure in port A will be reduced.

Section of 3-way direct operated pressure reducing valves

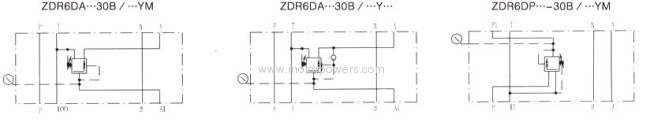

Symbol of 3-way direct operated pressure reducing valves

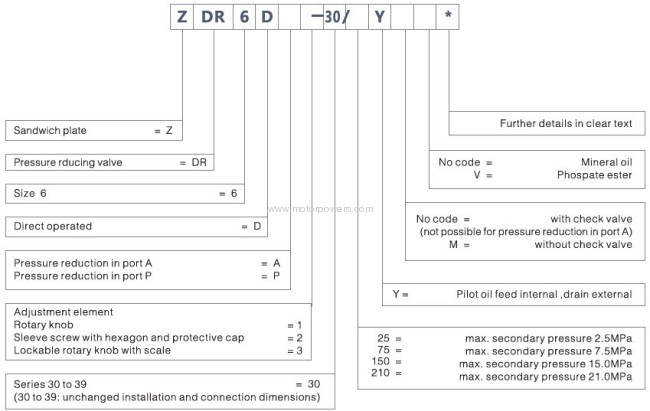

Ordering codes of 3-way direct operated pressure reducing valves:

Technical data of Pressure reducing valve direct operated of sandwich plate

Weight (kg) | Approx.1.2 |

Pressure Fluid | Mineral oil or Phospate ester |

Temperature range ℃ | -30~+80 |

Viscosity range mm²/s | 10~800 |

Max. operating pressure(inlet) Mpa | 31.5 |

Secondary pressure Mpa | To 21 |

Back pressure Mpa | To 6 |

Max. flow L/min | 30 |

Unit dimensions (dimensions in mm)