Electro-hydraulic operated valve with subplate mounting

10.0~100.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 20000pc/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

| Main Products: | Hydraulic Orbit Motor, Piston Hydraulic Motors, Rexroth Pump Part, A10V Pumps, Auto Hoist Power Units |

Product Detail

| Model No.: | 4WEH10 |

|---|---|

| Power: | Solenoid |

| Standard or Nonstandard: | Standard |

| Pressure: | High Pressure |

| Structure: | Control |

| Media: | Oil |

| Brand Name: | Power |

| Production Capacity: | 20000pc/month |

| Packing: | carton |

| Delivery Date: | 2 weeks |

Product Description

Features of Manual override electro-hydraulic directional control valve:

-Valves used to control the start, stop and direction of a fluid flow

-Electro-hydraulic operation (WEH), hydraulic operation (WH)

-For subplate mounting

- Spring or pressure-centered, spring or hydraulic offset

- Wet-pin DC or AC solenoids, optional

-Manual override, optional

- Electrical connection as individual or central connection

- Shifting time adjustment, optional

- Pre-load valve in the P-channel of the main valve, optional

- Auxiliary equipment:

Stroke adjustment at main spool, optional

Stroke adjustment and/or end position indicator, optional

Mechanical or inductive limit switch (proximity type) at the main spool, optional

Functional description, section of Manual override electro-hydraulic directional control valve:

Directional valves type 4WEH...

Valves of type WEH are directional spool valves with electro-hydraulic operation .

They control the start, stop and direction of a fluid flow.The directional valves basically consist of the main valve withhousing (1), main control spool (2), one or two return springs (3.1) and (3.2), and the pilot valve (4) with one or two solenoids "a"(5.1) and/or "b" (5.2).

The main control spool (2) in the main valve is held in the neutral or in the initial position either by the springs or by means of pressure. In the initial position, the two spring chambers (6) and (8) are connected to the tank without pressure via the pilot valve (4). The pilot valve is supplied with pilot fluid via the pilot line. The pilot oil supply can be either internal or external (external via port X). When the pilot valve is operated, e.g. solenoid "a", the pilot spool (1 0) is shifted to the left and thus spring chamber (8) is pressurized with pilot pressure. Spring chamber (6) remains

The main control spool (2) in the main valve is held in the neutral or in the initial position either by the springs or by means of pressure. In the initial position, the two spring chambers (6) and (8) are connected to the tank without pressure via the pilot valve (4). The pilot valve is supplied with pilot fluid via the pilot line. The pilot oil supply can be either internal or external (external via port X). When the pilot valve is operated, e.g. solenoid "a", the pilot spool (1 0) is shifted to the left and thus spring chamber (8) is pressurized with pilot pressure. Spring chamber (6) remains

un-pressurized.

The pilot pressure acts on the left side of the main control spool (2) and pushes it against the spring (3.1). As a

consequence, the ports P to B and A to T are connected in the main valv3.

When the solenoid is de-energized, the pilot spool returns to its initial position (exception: detente spool). The spring chamber (8) is unloaded to tank. The pilot oil is expelled from the spring chamber via the pilot

valve into the Y channel.

The pilot oil supply and drain are internal or external (external via port Y). An optional manual override (9) permits pilot spool (10) to be operated without energizing the solenoid.

4/3 -way directional valve with spring centring of the control spool. In this model, the main control spool (2) is held in the neutral position by two return springs (3.1) and (3.2). The two spring chambers (6) and (8) are connected to ports X and Y via the connector plate (11).

When one of the two ends of the main control spool (2) is pressurized with pilot pressure, the spool is moved to the shifted position. The required ports in the valve are then opened to flow.

When the pilot pressure is removed, the spring on the opposite side to the pressurized spool area causes the spool to return to its neutral or initial position.

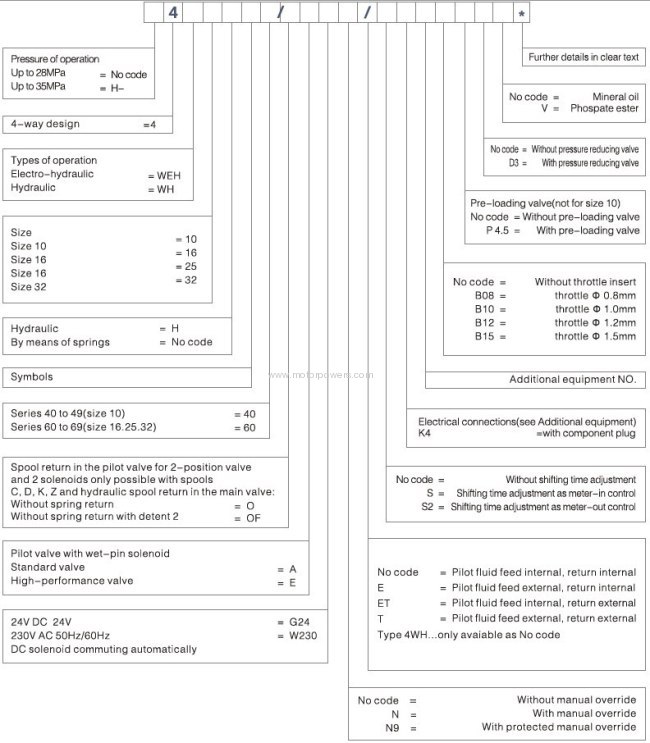

Ordering details of Electro-hydraulic operated valve with subplate mounting:

Unit dimensions (dimensions of 4WEH10 in mm)