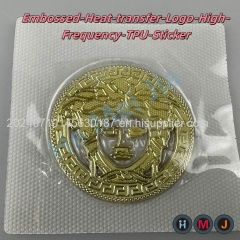

3D effect high raised TPU heat transfer label#patch#tag#brand#sticker#badges#crest#logo#brand#trademark

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Guangzhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Pattern: | Embossed |

| Type: | Self Adhesive |

| Material: | Rubber |

| Brand Name: | HMJ |

| tag: | brand |

| label: | badges |

| sticker: | patches |

Product Description

Materials Needed

TPU Sheets: Thermoplastic polyurethane sheets that can be molded and shaped under heat.

Molds: Custom molds designed to create the 3D effect and raised details.

Laser Cutter or Engraver: For precise cutting and detailing.

Heat Press: For transferring the label onto the desired surface.

Adhesive Layer: To help bond the TPU to the fabric or material.

Protective Film: To protect the design during the heat transfer process.

Software: Use graphic design software to create a detailed design of your label. The design should consider the 3D effect, with varying heights and depths.

3D Modeling: If available, use 3D modeling software to visualize the raised effect and adjust the design accordingly.

Custom Molds: Depending on the complexity of your design, you may need custom molds. These can be created using CNC machining or 3D printing.

Mold Material: Ensure the mold material can withstand high temperatures and repeated use.

Laser Cutting: Use a laser cutter to cut the TPU sheet into the desired shape and size based on your design. Ensure precision to maintain the integrity of the design.

Engraving Details: If needed, use the laser engraver to add fine details to the TPU that will be highlighted in the 3D effect.

Heating the Mold: Preheat the mold to the necessary temperature for shaping the TPU.

Pressing: Place the TPU sheet into the mold and apply heat and pressure. The TPU will take on the shape of the mold, creating the raised, 3D effect.

Cooling: Allow the TPU to cool in the mold to set the shape.

Adhesive Layer: Apply a heat-activated adhesive layer to the back of the molded TPU label.

Protective Film: Place a protective film over the front of the label to protect the design during the heat transfer process.

Preheating: Preheat your heat press according to the TPU and adhesive manufacturer's instructions.

Positioning: Place the item to be labeled on the heat press, position the TPU label on it, and cover with a protective sheet if necessary.

Pressing: Apply the heat press with the appropriate temperature, pressure, and time settings. This usually involves temperatures around 300-350°F (150-177°C) and pressing for 10-15 seconds.

Cooling and Peeling: Allow the label to cool slightly before carefully peeling off the protective film.

Test Runs: Perform test runs to ensure the mold, heat, and pressure settings yield the desired 3D effect.

Clean Surfaces: Ensure both the TPU and the surface to be labeled are clean and free of debris for optimal adhesion.

Safety Precautions: Follow all safety guidelines for using molds, laser cutters, and heat presses.

Fashion and Apparel: Adds a premium, high-end look to clothing and accessories.

Sporting Goods: Durable and resistant to wear and tear, suitable for sports gear.

Branding and Promotional Items: Eye-catching and tactile, ideal for branding purposes.