Product Description

The handheld fiber laser welding machine is a new generation of laser welding equipment, which belongs to non-contact welding. The operation process does not require pressure. Its working principle is to directly irradiate the surface of the material with a high-energy intensity laser beam. Through the interaction between the laser and the material, the material is melted internally, and then cooled and crystallized to form a weld.

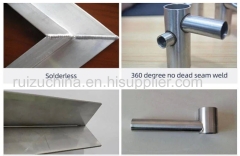

Product features

1. Easy to operate: Welding can be done by hand without the need for high training costs.

2. Fast and efficient, with a wide processing range: Laser welding machines have concentrated energy, efficient and high-speed welding, smooth and beautiful welds, and reduce subsequent polishing processes.

3. Wide range of weldable materials: stainless steel plate, iron plate, galvanized plate, aluminum plate and other metal materials can be welded.

4. Breaking through the limitations of workpiece shape and processing environment: small welding points, small heat affected area: no need to set up welding workbenches, occupying small space, flexible processing, fast welding speed, movable for long-distance operations, not limited by environmental space.

5. Low maintenance cost: Handheld laser welding equipment can complete welding operations as long as it is equipped with a handheld laser welding head. The cost of replacing accessories is low. If you don't understand how to replace them, you can take them to the manufacturer for direct maintenance without worrying about transportation and after-sales costs.

6. High cost-effectiveness: Manual handheld laser welding machines can not only perform handheld laser welding operations, but also engage in high-precision welding repair operations for molds through post installation platforms. They are the preferred cost-effective welding production equipment for more small-scale manufacturers