During circumferential seam welding the welding operation is performed using a welding manipulator arm in conjunction w

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Supply Ability: | 999 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HZKF1220-T |

|---|---|

| Brand Name: | luding |

| Weight: | 2500KG |

| Production Capacity: | 999 |

Product Description

HZK1220F-TD Automatic Tank Welding Machine

Technical specifications:

Model | HZKF1220-TD |

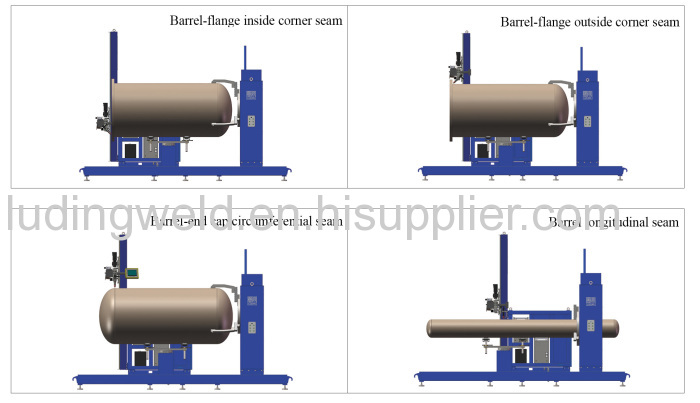

Joint Type(s) | Tank end cap circumferential seam, Barrel longitudinal seam, |

Three-jaw self-centering electric chuck | Three-jaw self-centering chuck, electric height adjustable. Central hole diameter: 515mm;Gripping outer diameter:Φ400~Φ1200mm; |

Lathe Headstock | Electric height adjustable on axial direction,capable for various weldmetns |

Support stand | Allows 180°horizontal rotation,electric height adjustable;Suitable weldment diameter: Φ400~Φ1200mm; |

Oscillator | Oscillation width: 0~40mm; Oscillation speed:0~20mm/s; Oscillation dwell time range: 0~5s |

Arc voltage controller | Standard slide track range: 0~40.0mm; Standard slide speed range: 0~6mm/s; |

Automatic wire feeder | Suitable for wire diameter: Φ1.0mm |

TIG torch | LD400 water-cooled TIG torch; |

Control Terminal | Color touchscreen control terminal |

Storage capacity | Able to store 40 sets of welding procedures |

Power source | Panasonic YC-400TX TIG power source |

Manipulator arm travel distance (X×Y×Z) (mm) | 3000×1200×30 |

Overall dimensions | 4500×2000×2600 |

Input power/ voltage/ frequency | Panasonic power source: 30KW/380V/50Hz, Control cabinet: 1.0KW/220V/50Hz |

Applicable joint type:

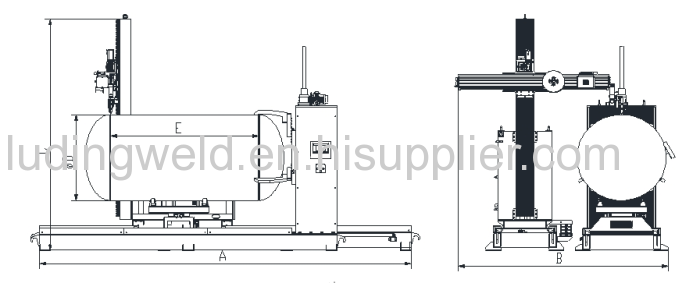

Overall dimensions:

Dimension | A Length | B Width | C Height | D Tank Diameter | F Longitudinal seam length | G Control cabinet |

HZK1220-T | 4500 | 2000 | 2600 | 400-1200 | 1000-2000(customizable) | 1000 |

Features of HZK1220-T Automatic Tank Welding Machine

1,This machine utilizes a fixed welding torch and a three-jaw self-centering electric chuck that clamps and rotates the weldment during welding. An Electric adjustable chuck for vertical height adjustment ensures efficient, secure clamping, minimizing manual labor involvement and a support stand enables 180° horizontal rotation for swift weldment turning.

2,Suitable for tank end cap circumferential seam, barrel longitudinal seam, corner seam between barrel and flange.

3,Suitable for welding various materials such as carbon steel, low-alloy steel, stainless steel.

4,Equipped with TIG welder.

5,Integrated design with compact and reliable structure

6,The operating system of the machine features a user-friendly touchscreen interface, facilitating effortless programming.

7,With a storage capacity for 40 sets of welding procedures, the system enables direct retrieval of the corresponding welding procedures based on specific weldment specifications.

8,Equipped with arc voltage controller (AVC) and oscillator (OSC).

9,The automatic wire feeder is equipped with automatic wire retraction and impulse wire feeding functions, ensuring precise and accurate wire feeding.

10,A forced circulation water cooling unit is built into the machine, guaranteeing reliable and uninterrupted operation for extended periods.

11, The machine features a one-touch operation that automates the entire welding process. It also allows real-time intervention for adjusting welding parameters as needed.