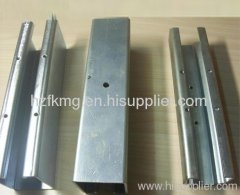

Stamped Sheet Metal Parts

| Place of Origin: | Guangdong |

|---|

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Agent, Association |

Product Description

Stamped Sheet Metal Parts

Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil pressing machine 3 sets and riveting machine, hole pumping machine, tapping machine, drilling machine and other sheet metal processing equipment.

Sheet metal processing commonly used materials

galvanized steel plate SECC

The base material of SECC is general cold-rolled steel coil, which becomes electrogalvanizing product after continuous electrogalvanizing production line goes through degreasing, pickling, electroplating and various post-treatment processes. SECC not only has the mechanical properties and similar machinability of ordinary cold rolled steel sheet, but also has superior corrosion resistance and decorative appearance. In the electronic products, home appliances and furniture market has a great competitiveness and substitution. For example, SECC is commonly used in computer cases.

ordinary cold rolled sheet SPCC

SPCC refers to the continuous rolling of steel ingot into steel coil or sheet of required thickness by cold rolling mill. SPCC surface without any protection, exposure to the air is easy to be oxidized, especially in the humid environment, the speed of oxidation, dark red rust, in use to spray paint, electroplating or other protection surface.

hot dip galvanized steel SGCC

Hot-dip galvanized steel coil refers to the semi-finished product after hot pickling or cold rolling, after cleaning, annealing, immersed in the temperature of about 460°C melt zinc tank, the steel sheet plated with zinc layer, and then after quenching and leveling and chemical treatment. SGCC material is harder than SECC material, has poor ductility (avoiding deep pumping design), thicker zinc layer, and poor weldability.

stainless steel SUS304

One of the most widely used stainless steel, containing Ni (nickel) than Cr (chromium) steel is rich in corrosion resistance, heat resistance, with very good mechanical properties, no heat treatment hardening phenomenon, no elasticity.

stainless steel SUS301

Cr (Chromium) content is lower than SUS304, poor corrosion resistance, but after cold processing in stamping processing can get a good tension and hardness, good elasticity, used for spring and anti EMI.

As one of the stamped sheet metal parts manufacturers, we provide rapid cnc prototyping, oem metal stamping, metal sheet stamping parts, stamped sheet metal parts, sheet metal stamping parts, rapid cnc prototyping, etc. For more information, please feel free to contact us!