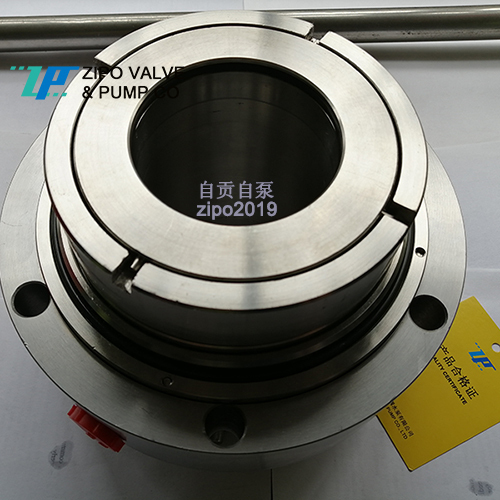

Hard alloy and stainless steel cartridge mechanical seal with single sealing surface or double sealing surface

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Zigong, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ZCMSS/D |

|---|---|

| Means of Transport: | Ocean, Air |

| Standard or Nonstandard: | Standard |

| Style: | Mechanical Seal |

| Material: | Metal |

| Brand Name: | ZP |

| Production Capacity: | 1000 |

| Packing: | plywood case or carboard box |

| Delivery Date: | 25 days |

Product Description

Hard alloy and stainless steel cartridge mechanical seal with single sealing surface or double sealing surface

Contact: Email: zipopvf#163.comWechat: zipo2019; QQ: 2191417589;

Mechanical seal products are special products. The price will change relatively according to different materials, sizes, structures and purchase quantities. Mechanical seal can be customized made according to your sample; at the same time, we can go to the customer site to measure mechanical seal and tailor-make for you. Please tell us the exact pump type, shaft diameter, mechanical seal installation size and other parameters before you consult or purchase our products.

This kind of single sealing surface or double sealing surface cartridge mechanical seal is specially designed for ZCP or ZBG chemical process pump and ZSP or ZZ or ZN slurry pump of ZIPO VALVE & PUMP CO., LTD.

The unique compensation ring static structure and spring external structure of the mechanical seal ensure the long-term effective operation of the mechanical seal under the conditions of high concentration, high particle content and easy crystallization. The mechanical seal is specially equipped with the cooling water guide sleeve according to the operation characteristics of heavy chemical pump, which is more suitable for the working conditions of high temperature, high speed and high pressure.

The material of the mechanical seal is cemented carbide+304+fluororubber, or silicon carbide+316L+perfluoroether. The former is suitable for alkaline medium with moderate corrosion, and the later is suitable for phosphoric medium and hydrochloric medium with strong corrosion.

Product features:

1. High temperature resistance, corrosion resistance, wear and high pressure;

2. Spring received effective protection, balanced structure;

3. Good sealing performance, long service life.

4. It is not necessary to measure the working length of the mechanical seal during installation;

5. The shaft can be adjusted at any time;

6. There will be no leakage during startup, because the seal has been tested in advance;

7. It is only necessary to set the tight cover bolt during installation, and the assembly quality is easy to guarantee;

8. Before installation or startup, the sealing surface is protected well from contamination by sundries or damage due to operation errors;

9. It can be readjusted after thermal expansion of the machine and equipment;

10 It is easy to take out the mechanical seal for cleaning and inspection without dismantling the pump equipment.

Seal type: double face seal or single face mechanical seal (selected according to actual medium working condition)

Cooling mode: internal flushing cooling or with external flushing water nozzle (selected according to actual medium, temperature and other working conditions)

Shaft diameter: 35mm ~ 350mm

Applicable medium: limestone, gypsum slurry and other media containing solid particles and corrosive medium

Applicable temperature: for internal flushing cooling water, the applicable medium temperature is below 60 ℃; for external flushing cooling, the applicable medium temperature is 60 ℃ ~ 150 ℃

Mechanical seal model code: ZCMS-30, ZCMS-35, ZCMS-40, ZCMS-45, ZCMS-50, ZCMS-55, ZCMS-60, ZCMS-65, ZCMS-70, ZCMS-75, ZCMS-80, ZCMS-85, ZCMS-90, ZCMS-95, ZCMS-100, ZCMS-110, ZCMS-120, ZCMS-125, ZCMS-130, ZCMS-140, ZCMS-150,ZCMS-160,ZCMS-170, ZCMS-180, ZCMS-190, ZCMS-200, ZCMS-300, ZCMS-350

Mechanical seal can be applicable for the following pump model codes:

1. Chemical pump model code:

ZCP/ZBG50-32-125~ZCP/ZBG50-32-250B,ZCP/ZBG65-50-125~ZCP/ZBG65-50-160A,ZCP/ZBG80-65-125~ZCP/ZBG80-65-160A,ZCP/ZBG80-50-200~ZCP/ZBG80-50-315,ZCP/ZBG100-80-125~ZCP/ZBG100-80-160,ZCP/ZBG100-65-200~315,ZCP/ZBG150-125250~400,ZCP/ZBG200-150-250~400,ZCP/ZBG250-150-250~400A

2. Axial flow pump model code: ZAP/ZWX-300, ZAP/ZWX-400, ZAP/ZWX-500,ZAP/ZWX-600,ZAP/ZWX-700,ZAP/ZWX-800,ZAP/ZWX-900,ZAP/ZWX-1000, ZAP/ZWX-1200, ZAP/ZWX-1500

3. Slurry pump model code: 50ZSP/ZZ-33,50ZSP/ZZ-46,80ZSP/ZZ-33,80ZSP/ZZ-36,80ZSP/ZZ-39,80ZSP/ZZ-42,80ZSP/ZZ-52,100ZSP/ZZ-33,100ZSP/ZZ-36,100ZSP/ZZ-39,100ZSP/ZZ-42,100ZSP/ZZ-46,100ZSP/ZZ-50,150ZSP/ZZ-42,150ZSP/ZZ-45,150ZSP/ZZ-48,150ZSP/ZZ-50,150ZSP/ZZ-55,150ZSP/ZZ-58, 150ZSP/ZZ-60,150ZSP/ZZ-63,150ZSP/ZZ-65, 150ZSP/ZZ-70, 150ZSP/ZZ-74, 150ZSP/ZZ-78, 200ZSP/ZZ-48,200ZSP/ZZ-53,200ZSP/ZZ-58,200ZSP/ZZ-60,200ZSP/ZZ-63,200ZSP/ZZ-65,200ZSP/ZZ-70,250ZSP/ZZ-55,250ZSP/ZZ-60,250ZSP/ZZ-70,250ZSP/ZZ-80,300ZSP/ZZ,400ZSP/ZZ 450ZSP/ZZ

4. Mud pump model code: 25ZND, 40ZNG, 50ZND, 80ZND, 80ZNG, 80ZNG80,100ZNDI,100ZND27,100ZND36,100ZNG,100ZNG40,100ZNG46,100ZNG47,100ZNG53,100ZNG60,100ZNG75,100ZNG90, 150ZND150ZND28,150NG40, 150ZNG51,150NG, 150ZNG75, 150ZNG90, 200ZND, 200ZND37, 200ZND28, 200ZNG43, 200ZNG, 200ZNG75, 200ZNG90, 200ZNG100, 250ZND, 250ZNG, 250ZNG75, 150ZNG55, 150ZNG67, 150ZNG90, 200ZNG65, 200ZNG70, 200ZNG75.

Manufacturer: ZIPO VALVE & PUMP CO., LTD