Wear-resistant AZM brick 1550 Silica Mullite Bricks for cement

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB,CFR,DDP,EXW |

| Payment Terms: | Paypal, L/C, T/T |

| Supply Ability: | 100000 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 230*114*65mm |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | ZHENJIN |

| Material:: | SiC Mullite Wear-Resistant brick |

| SiO2 Content (%):: | customizable |

| MgO Content (%):: | ≥30 |

| Refractoriness (Degree):: | Common (1580°< Refractoriness< 1770°) |

| SiC Content (%):: | customizable |

| Product name:: | Silicon mullite brick |

| Application:: | Industrial Furnaces |

| Apparent porosity: | 19% |

| Packing:: | Standard Wooden Pallet |

| apparent porosity:: | 18% Max |

| Production Capacity: | 100000 |

| Packing: | be packed by Pallet+Paper or Steel angle bead+Paper board +Plastic |

| Delivery Date: | 15 days or to be negotiated |

Product Description

Introduction of Silicon mullite brick

Silicon mullite wear-resistant bricks use high-quality silicon carbide and high-purity clay as the main raw materials, use refractory materials and other complex-phase modifications, add ultra-fine oxides and specific additives to make this series of products surface at high temperatures Form a dense glaze film, prevent the refractory lining from reacting with the material, delay the penetration and erosion rate, and make the silicon mullite wear-resistant brick have high resistance to chemical erosion and excellent wear resistance. Silicon mullite wear-resistant brick is the best material for the transition zone and preheating zone of large cement kiln.

Advantage of Silicon mullite brick

1. Good wear resistance, can effectively protect the cement kiln

2. Silicon mullite wear-resistant brick has good spalling resistance and high compressive strength

3. High thermal stability and dense tissue structure

4. Energy saving and environmental protection. Silicon mullite wear-resistant bricks can save 3 million yuan per year for enterprises, and meet environmental protection requirements

Index of Silicon mullite brick

Model | ZJAS-1680 | ZJAS-1650 | ZJAS-1550 |

MgO(%) | ≥30 | ≥30 | ≥30 |

Fe2O3(%) | ≥65 | ≥63 | ≥60 |

Bulk density(g/cm³) | ≥2.65 | ≥2.60 | ≥2.50 |

Apparent porosity(%) | ≤16 | ≤17 | ≤18 |

Normal temperature compressive strength(MPa) | ≥90 | ≥90 | ≥80 |

refractoiness under load(0.2Mpa,t0.6) | ≥1680℃ | ≥1650℃ | ≥1550℃ |

Thermal shock stability, times (1100℃, water cooling) | ≥15 | ≥15 | ≥15 |

Wear coefficient | ≤6 | ≤7 | ≤8 |

Application of silica mullite wear-resistant brick

It is suitable for the transition zone, preheating zone, tertiary air duct, five-stage preheater and lime kiln discharge chute of cement rotary kiln.

company profile

Zhengzhou Zhenjin refractory material CO., Ltd. was established in 1985 and is located in Xinmi City, Henan Province, a refractory production base in China. It covers an area of about 70,000 square meters. It is a company integrating R&D, production, sales,international trade and technical services. An integrated manufacturing enterprise. The company is committed to the provision,construction and installation of refractory products in the cement industry, glass industry, building materials industry,non-ferrous smelting and metallurgical industries and other personalized services.

Zhengzhou Zhenjin refractory material CO., Ltd. has long been focusing on the research and development and production of high-quality refractories. At the same time, it has also developed and produced magnesia-aluminum spinel bricks, magnesia-iron tip Refractory bricks such as spar bricks have successively created a number of safe use records in the cement industry.

The company's products are exported to Greece, South Korea, Japan, Canada, Chile, Mongolia, Cambodia and other international markets. The products have won the trust and praise of users for their stable performance, excellent quality and exquisite craftsmanship. Our company has always been adhering to the business policy of "customer interests first", aiming at international refractory production standards, integrating resources, and further enhancing the company's core competitiveness in the field of refractory manufacturing.

Our products are exported to South Korea, Japan, the United States, Canada, Chile, Mongolia, Cambodia, Angola and other international markets. Our products have won the trust and praise of users for their stable performance, excellent quality and exquisite craftsmanship.

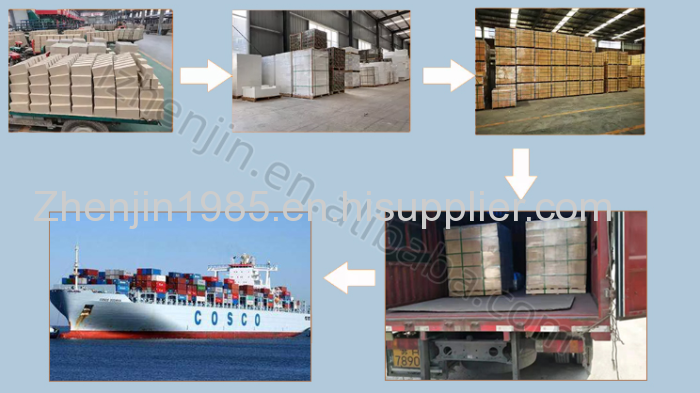

Packing and shipping

1,magnesium alumina spinel brick will be packed by Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film or according to customer's requirements.

2,We will deliver the goods on time, with guaranteed quality and quantity, in full accordance with the contract and customer requirements.

3,With superb technology, excellent product quality and service, Zhenjin has obtained your cooperation and support. Continuing to provide quality services is our unremitting pursuit.

FAQ

Q1 : How can you control your quality?

A1 : For each production processing, ZhenJin have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q2 : What is your lead time?

A2 : It usually needs about 15- 20 days after receiving the PO.

Q3 : Can we visit your company?

A3 : Yes, surely. You are very welcome to China and we will be honored to have a customer and friend.

Q4 : What is the warranty of your products?

A4 : Our products have at least 1 year warranty,if any quality problems,we will take responsibility of the cost of the shipment and the replacement.

Q5. What's your payment terms?

A5:We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.