China Factory Supplier fused magnesite brick low price Magnesia Refractory Brick for kiln

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CPT |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100000 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 230*114*65mm |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | ZHENJIN |

| Industrial high temperature supplies: | refractory matter |

| Place of Origin: | Henan, China |

| Shape: | Brick |

| Material: | Magnesia |

| SiO2 Content (%): | 1% |

| Al2O3 Content (%): | customizable |

| MgO Content (%): | 91% |

| CaO Content (%): | customizable |

| Refractoriness (Degree):: | Common (1580°< Refractoriness< 1770°) |

| CrO Content (%): | customizable |

| Production Capacity: | 100000 |

| Packing: | be packed by Pallet+Paper or Steel angle bead+Paper board +Plastic |

| Delivery Date: | 15 days or to be negotiated |

Product Description

Introduction of Magnesia Refractory Brick

Magnesia brick is an alkaline refractory material with a magnesium oxide content of more than 90% and periclase as the main crystal phase. Generally, it can be divided into two categories: sintered magnesia bricks (also known as fired magnesia bricks) and chemically bonded magnesia bricks (also known as unfired magnesia bricks). Magnesia bricks with high purity and firing temperature are called directly bonded magnesia bricks because of the direct contact of periclase grains; bricks made of fused magnesia as raw materials are called fused rebonded magnesia bricks.

Magnesia bricks have high refractoriness, good alkali slag resistance, high load softening temperature, but poor thermal shock resistance. Sintered magnesia bricks are made of magnesia bricks. After crushing, batching, kneading and molding, they are fired at a high temperature of 1550-1600°C, and the firing temperature of high-purity products is above 1750°C.

Magnesia brick usage scenarios

Magnesia bricks are mainly used for steelmaking open hearth furnace, electric furnace bottom and furnace wall, permanent lining of oxygen converter, non-ferrous metal smelting furnace, high temperature tunnel kiln and cement rotary kiln lining, furnace bottom and furnace wall of heating furnace, glass kiln Regenerator etc.

Advantages of magnesia bricks

Magnesia bricks are alkaline refractory materials, so they have strong resistance to alkali erosion

Strong erosion resistance, high compressive strength, high refractoriness, can withstand high temperature without losing structural integrity

High load softening temperature and high purity, magnesia bricks are usually made of high-purity raw materials to ensure their quality and consistency

Long service life, magnesia bricks are durable, reducing the cost of frequent replacement and maintenanceMagnesia brick usage scenariosMagnesia bricks are mainly used for steelmaking open hearth furnace, electric furnace bottom and furnace wall, permanent lining of oxygen converter, non-ferrous metal smelting furnace, high temperature tunnel kiln and cement rotary kiln lining, furnace bottom and furnace wall of heating furnace, glass kiln Regenerator etc.

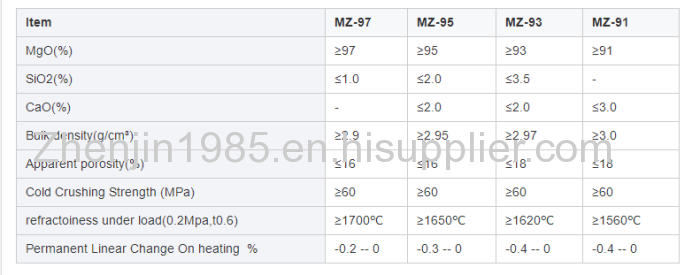

Physical and chemical indicators of Magnesia Refractory Brick

Company profile

Zhengzhou Zhenjin refractory material CO., Ltd. founded in 1985, is located in Xinmi City, Henan Province of China. ZHENJIN REFRACTORIES is a refractory-manufacturing enterprise integrating research and development, production, sales, international trade and technical services. The company is committed to cement industry, glass industry, non-ferrous smelting and steel & iron industry to provide products, construction and installation and tailor services.

ZHENJIN REFRACTORIES has two lines of burnt basic bricks, one line of alumina-silica shaped refractory, as well as one line of unshaped refractory production. There are three super-high temperature tunnel kilns up to 1850℃, with the total capacity of about 100,000 tons/annual of various type refractories. ZHENJIN REFRACTORIES has long focused on technological innovation and modern equipment investment, automatic production of programming dosage, two hydraulic presses of 2500-ton. All the cement bricks have to pass the multi-functional finishing line, imported from Europe, in order to sort bricks beyond the tolerance, to stick card board and to mark brand.

our services

FAQ