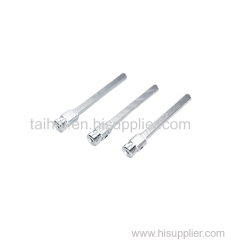

Precision Hardware Parts Processing with Centering Machine

0.38 RMB

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, D/P, T/T |

| Supply Ability: | 3000/1 day |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TH01 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | taihai |

| Production Capacity: | 3000/1 day |

| Packing: | Ordinary packaging |

| Delivery Date: | 1-3 days |

Product Description

Walking machine machining is a type of precision manufacturing that can quickly and accurately produce very small parts. In addition to machining turning parts such as screws, walking machines can also produce complex parts with no turning surface at all!

The advantage of a centrifuge lathe is that it is both accurate and fast. It can maintain tolerances as small as tens of thousands of inches, and some parts may only be processed in 10 seconds! The working principle of a centrifuge is very similar to 5-axis machining, providing functions such as boring, boring, knurling, turning, and milling, as well as external thread cutting, tapping, rolling, and single point thread processing