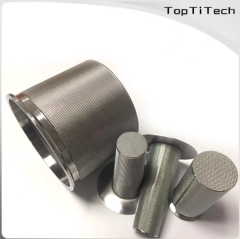

50 microns Multiple Layers Mesh Cylinder Filter Element

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 500000 pieces/week |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | MF-03 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | TopTiTech |

| Product Name: | 5mm Sintered stainless steel Multi-Layer Wire Mesh Laminated plate |

| Material: | stainless steel |

| Size: | customized |

| Filter Precision: | 0.2-100μm |

| Porosity: | 30%-40% |

| Operating Temperature: | ≤600℃ |

| Technique: | Powder sintering |

| MOQ: | 1 Piece |

| Packing: | wooden box, carton box |

| Production Capacity: | 500000 pieces/week |

| Packing: | Standard packing |

| Delivery Date: | 3 days for ready goods, 15 days for OEM |

Product Description

Product Introduction

The Sintered Stainless Steel Multi-Layer Wire Mesh Laminated Plate is a product constructed by overlapping multiple layers of woven wire mesh and subsequently sintering them in a vacuum furnace under high temperatures and pressures. This process enhances the strength and overall durability of the material while ensuring uniform filter aperture distribution. By addressing the limitations of individual layers such as reduced strength, poor rigidity, and unstable aperture size, this sintered multi-layer wire mesh plate offers a balanced combination of filter rating, permeability, and robustness.

Ideal for applications demanding high filter accuracy, resistance to pressure differentials, abrasion, heat, cold, and processing, this product finds utility across various industries including petrochemicals, nuclear, synthetic fibers, pharmaceuticals, food, and aerospace.

Sintering can be applied to various types of woven wire meshes, effectively bonding all wires together to prevent medium migration. Through the vacuum furnace sintering process, the wires are fused securely, ensuring stability and eliminating the risk of component failure or malfunctions in critical applications such as medical or hydraulic fluid filtration. Once sintered, the mesh structure remains fixed, preventing wire movement under pressure and ensuring consistent aperture sizes throughout its service life.

Specification

Material: Stainless steel wire

Filtration precision: 1um

Technic: Woven, vacuum sintering

Layers: 5 layers

Width: 20mm

Length: 100mm

Thickness: 5mm

What is the structure of 5-layers stainless steel wire mesh plate?

The structure of TOPTITECH's five-layer laminated board, a widely adopted sintered wire mesh design, involves layering a single fine wire mesh between two thicker square woven meshes and enclosing them within two robust Dutch woven metal wire meshes. This configuration is sintered to create a solid plate, with the subtle wire mesh acting as the filter bed. Customizable to specific filtration requirements ranging from 1 micron to 200 microns, this design offers versatility and precision in filtration applications.

Advantage:

1. Enhanced Filtration Efficiency: TOPTITECH Sintered Stainless Steel Multi-Layer Wire Mesh Laminated Plate provides high filtration efficiency due to their multi-layer construction and precise filter ratings, ensuring effective removal of contaminants and impurities from gas, liquids, and solids.

2. Uniform Filter Aperture: The Sintered Stainless Steel Multi-Layer Wire Mesh Laminated Plate offers a uniform filter aperture, ensuring consistent filtration performance and reliable separation of particles across the entire filtration surface.

3. High Strength and Durability: TOPTITECH Sintered Stainless Steel Multi-Layer Wire Mesh Laminated Plates are sintered in a vacuum furnace, resulting in enhanced strength, rigidity, and durability compared to traditional filtration materials.

4. Stability Under Pressure: The sintering process ensures that the wires in TOPTITECH Sintered Stainless Steel Multi-Layer Wire Mesh Laminated Plates are firmly fused in place, preventing wire movement under pressure. This stability maintains the integrity of the filtration structure and prevents aperture size variations during use.

Application:

1. Filtration in Petrochemical Industry: Used for precise filtration of chemicals, gas, and liquids in petrochemical processes to ensure product purity and process efficiency.

2. Pharmaceutical Industry: Applied for filtration in pharmaceutical production to remove contaminants and ensure the purity of pharmaceutical products.

3. Food Industry: Used for filtration processes in food production to meet hygiene and safety standards by removing particles and impurities from food products.

4. Aerospace Industry: Employed for filtration applications in aircraft hydraulic systems to ensure the purity of hydraulic fluids and prevent system malfunctions.

5. High-Pressure Fluid Filtration: Suitable for applications requiring high-pressure fluid filtration, such as hydraulic systems, where precise and stable filtration is essential for system performance and longevity.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer´s designated place without damage.

Contact Us

TEL: +8619992203758

Company: TOPTITECH _ BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China