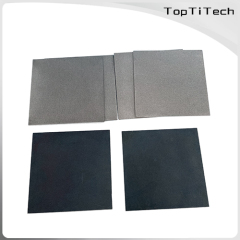

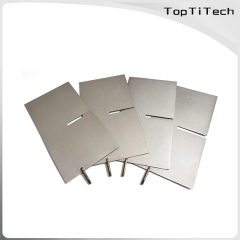

Titanium electrode plate for water treatment

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 500000 pieces/week |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TE-01 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | TopTiTech |

| Product Name: | Titanium electrode plate for water treatment From Toptitech |

| Material: | Titanium |

| Size: | customized |

| Filter Precision: | 0.2-100μm |

| Porosity: | 30%-40% |

| Operating Temperature: | ≤600℃ |

| Technique: | Powder sintering |

| MOQ: | 1 Piece |

| Packing: | wooden box, carton box |

| Production Capacity: | 500000 pieces/week |

| Packing: | Standard packing |

| Delivery Date: | 3 days for ready goods, 15 days for OEM |

Product Description

Product Introduction

Titanium electrode plate for water treatment is a platinum group noble metal oxide with high electrocatalytic performance, strong oxidation resistance, and good electrical conductivity coated on a pure titanium substrate, which is an insoluble anode.

First of all, this kind of titanium anode has the characteristics of light specific gravity, good strength, corrosion resistance, and good performance, especially the wet chlorine resistance performance is unmatched by other metal materials. For example: when there is a small number of chloride ions in the electrolysis of water, the stainless steel plate will quickly undergo pitting corrosion. This will decrease the electrode's lifespan, whereas titanium does not have these issues.

Secondly, because a variety of platinum group noble metals are added to the coating, it has high current efficiency, good electrical conductivity, good electrocatalytic performance, strong oxidation resistance, long working life and energy saving.

Product parameters

Product name: Titanium electrode plate for water treatment

Brand: TOPTITECH

Product base material: Gr1 pure titanium

Product coating: Ru/Ir/Pt (ruthenium iridium platinum)

Product process: nano coating - high temperature sintering

Specifications: customized according to customer requirements

Product performance:

1. It has excellent properties such as corrosion resistance, high temperature resistance, high strength, easy guarantee of filtration accuracy, and easy regeneration; The plates is sintered at high temperature, so the surface particles are not easy to fall off; in the air the temperature in use can reach 300°C;

2. It is suitable for filtering various corrosive media, such as: weak hydrochloric, sulfuric, hydroxide, sea water, aqua regia, and chloride solutions such as iron, copper, and sodium;

3. It has excellent mechanical properties, can be machined for cutting, welding, etc., has high compressive strength, and the internal pressure breaking strength is as high as 0.3MPa;

4. The regeneration method is simple and can be reused after regeneration.

Craftsmanship

Firstly, all raw materials are monitored. When metal powder is analyzed, in addition to its metallurgical composition, its particle size distribution, bulk ratio, etc. are analyzed. After being formed by cold isostatic pressing, it is sintered at high temperature and high vacuum. It is necessary to detect the carbon content before and after the sintering operation. Each batch of products produced needs to be tested for bubble point. The hardness of the medium has been determined. The diameter of spherical particles also needs to determine their permeability, density and carbon content.

Applications

1. Production of sodium hypochlorite via electrolysis in the chlorate and chlor-alkali industries

In the production of chlor-alkali, pure saturated salt water is used as electrolytic solution, titanium electrode is used as anode, and asbestos wool attached to iron mesh is used as cathode. The anode chamber produces chlorine gas, and the cathode chamber produces sodium hydroxide. After purification, it is widely used in various industries. in industrial production.

An epoch-making contribution to the science of electrochemistry has been made by the use of titanium anode, which has significantly aided the growth of the chlor-alkali sector. The electrode has high catalytic activity for chlorine analysis and has good electrocatalytic activity, mechanical stability, and chemical stability for chlorine analysis reaction, so It is an irreplaceable electrode material in today's chloralkali industry, and it has a lifespan of over five years.

2. Electrolyzed functional water

Water that has been artificially treated to achieve a variety of beneficial purposes is referred to as functional water. With its high practicability, good sterilization effect, and lack of secondary pollution, electrolyzed water is a well-liked sterilization treatment technique. Titanium electrodes, which are frequently used in electrolyzed water machines, are used to electrolyze drinking water or trace salt water to generate functional water.

1) Using electrolysis to generate hypochlorite, new ecological oxygen, hydroxyl radicals, and other strong oxidizing substances to kill microorganisms.

2) Directly kill germs by acting on them with electrolytic electrodes.

3) Alkaline ionized water can directly treat a variety of diseases, effectively improve the metabolic function of the human body, eliminate harmful acidic metabolite free radicals, and enhance physical fitness to prevent and improve disease resistance.

4) Acidic ionized water has the effect of inhibiting the growth of bacteria, the effect is the same as that of astringent water for beauty, and it should be sterilized with strong oxidation.

3. Cathodic protection

In the ocean, ship hull, bridge, and other steel use environments, due to the corrosion of impurities in the steel and micro-batteries, coupled with the complex natural environment, although corrosion-resistant alloy steel is selected and the thickness of the material is increased to coat excellent corrosion-resistant paint, these The corrosion of structures is still very serious, which poses a great threat to safe production, and cathodic protection is a convenient and important measure to effectively protect permanent steel structures in the ocean. Using an applied current to make the entire surface of the protected metal structure becomes a cathode is called impressed current cathodic protection. Or connect a metal or alloy with a more negative potential to the metal equipment that needs protection, which is called sacrificial anode protection.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

+8619992203758

Company: TOPTITECH _ BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China