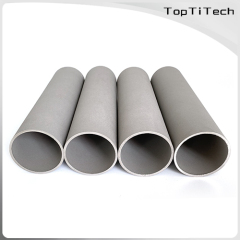

10 Micron Titanium Porous Filter Tube for Flow Control

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 500000 pieces/week |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TF-02 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | TopTiTech |

| Product Name: | 10 Micron Titanium Porous Filter Tube for Flow Control |

| Material: | Titanium powder |

| Size: | customized |

| Filter Precision: | 0.2-100μm |

| Porosity: | 30%-40% |

| Operating Temperature: | ≤600℃ |

| Technique: | Powder sintering |

| MOQ: | 1 Piece |

| Packing: | wooden box, carton box |

| Production Capacity: | 500000 pieces/week |

| Packing: | Standard packing |

| Delivery Date: | 3 days for ready goods, 15 days for OEM |

Product Description

Product Introduction

Sintered metal powder filter elements are advanced filter components that have undergone the meticulous process of sintering. This technique enhances their porosity, enabling their versatile use in applications ranging from liquid and gas filtration to gas/liquid flow regulation and ventilation tasks.

Distinguished from alternative filter materials like glass fiber, stainless steel wire mesh, ceramics, and filter paper, sintered metal filters exhibit superior mechanical and compressive strength. Particularly in environments with sustained high temperatures and corrosive conditions, sintered metal filter elements excel in refining the filtration process while curbing operational expenses.

Specifications

Material: Grade 1 Titanium Powder

Diameter: 20mm

Length: 200mm

Pore Size: 10 Micron

Connector: Quick-Release Connector

Temperature Resistance: Up to 300°C

Features

Reusability and adaptability

Exceptional filtering efficiency

High tolerance to thermal shock

Extended service life (cleanable and reusable)

Resilient to high pressure and temperature

Sturdy and fracture-resistant

Corrosion-resistant

Exceptional thermal shock resistance

Offers a range of geometric possibilities

Maintains fine tolerance to preserve physical properties

Applications

Removal of dust, bacteria, and oil fog from gas and steam

Noise reduction and gas buffering

Catalyst recycling

Decarburization filtration

Filtration of viscous liquids

Filtration of strong polar solvents

Particle retention in off-gas from fluidized beds

Filtration and separation in pharmaceutical, beverage, food, metallurgy, petroleum, and other industries

Manufacturing Process of Sintered Metal Filters

The production of sintered metal filters involves pressing metal powder into a customized mold with precise pressure to ensure particle adhesion at contact points. The 'green' strength of the part pre-sintering is contingent upon various factors of the metal powder like particle size, composition, and shape. Following molding, the 'green' part undergoes controlled heating or sintering at a temperature below the metal's melting point, allowing for controlled shrinkage. The sintering process transforms the original powder particles into a fully interconnected porous metal structure, dictating the filtration medium's micron class. Moreover, the porosity of the sintered medium is a defining characteristic, tailored to the specific demands of individual systems.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

+8619992203758

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China