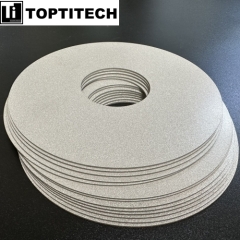

10 Micron Porous Titanium Disc Filter Element

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100000pcs/week |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Structure: | Panel Filter |

| Material: | Others |

| Function: | Water Filter |

| Brand Name: | TOPTITECH |

| Production Capacity: | 100000pcs/week |

| Packing: | wooden case or carton box |

| Delivery Date: | in 15-20 days |

Product Description

10 Micron Porous Titanium Disc Filter Element

Sintered porous titanium disc is a type of porous titanium filter element. It is manufactured using industrial high-purity titanium powder (99.6% purity, with 0.4% consisting of titanium alloy elements such as nitrogen, hydrogen, iron, manganese, etc.). The production process involves sieving, cold isostatic pressing, and high-temperature, high-vacuum sintering.

At TOPTITECH, our porous metal titanium discs are the preferred choice for gas diffusion layers and electrode plates in high-performance electrolyzers and fuel cells. These discs exhibit uniform porosity, excellent strength, and enhanced corrosion resistance, resulting in superior overall performance. Additionally, our porous titanium plates are available in various operating temperatures suitable for fuel cells. Furthermore, they can be coated with platinum or other catalyst layers to further enhance performance.

Specifications:

- Size: 178*1.6mm

- Pore Size: 10 microns

- Material: pure titanium powder(GR1)

- Temperature Resistance: up to 300℃

- Porosity: 30%-40%

Feature

1. Superior Porosity: The disc exhibits a uniform and controlled porosity, allowing for efficient and precise filtration. This enables the disc to effectively trap and remove impurities, particulate matter, and contaminants from /or liquids.

2. Strength and Durability: The manufacturing process involving cold isostatic pressing and high-temperature sintering results in a structurally robust and durable disc. It can withstand high pressures and maintain its integrity even in demanding operating conditions.

3. Corrosion Resistance: Titanium, known for its exceptional corrosion resistance, ensures that the porous disc remains unaffected by corrosive environments. This extends the disc's lifespan and ensures consistent filtration performance over time.

4. Versatility in Applications: The porous titanium disc finds extensive use in various industries and applications. It is commonly employed in gas diffusion layers and electrode plates for high-performance electrolyzers and fuel cells. Additionally, it is utilized in industries such as chemical processing, pharmaceuticals, food and beverage, and environmental monitoring.

Applications:

1. Chemical Industry: The sintered porous titanium filter disc effectively removes impurities and particulate matter from /used in chemical manufacturing processes, ensuring product quality and safety.

2. Pharmaceutical Industry: It plays a crucial role in gas purification for pharmaceutical production, eliminating contaminants and maintaining sterile environments.

3. Food and Beverage Industry: Gas purification using the titanium filter disc ensures the removal of unwanted particles, odors, and contaminants, meeting stringent quality standards.

4. Electronics Industry: It is utilized in gas purification processes for semiconductor manufacturing, preventing particle contamination and ensuring high product yields.

5. Environmental Protection: The filter disc assists in purifying /in environmental monitoring and control systems, contributing to cleaner air and reducing pollution.