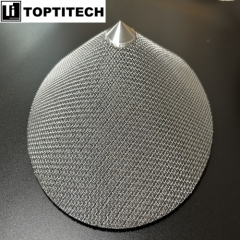

Sintered Conical Wire Mesh Filter Strainer

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100000pcs/week |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SS 316L |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Welded |

| Material: | Others |

| Application: | Filter |

| Brand Name: | TOPTITECH |

| Production Capacity: | 100000pcs/week |

| Packing: | wooden case or carton box |

| Delivery Date: | in 15-20 days |

Product Description

Sintered Conical Wire Mesh Filter Strainer

The sintered conical wire mesh filter strainer is meticulously crafted from stainless steel sintered wire mesh through precise cutting and welding techniques. The utilization of a rolling seam welding process guarantees exceptional roundness and flatness. Thanks to its cone-shaped design, the sintered cone filter offers superior diversion, separation, and filtration capabilities.

Tailored to meet customers' preferences, the bottom of the stainless steel sintered mesh cone filter can either be flat or pointed. Whichever configuration is chosen, this filter exhibits remarkable dirt-holding capacity, making it a popular choice for three-in-one filtration purposes encompassing filtering, washing, and drying applications across various industries such as chemistry, food processing, beverage, and pharmaceuticals, among others.

Parameters

Material: 316 L stainless steel, 304 stainless steel

Filtration precision: 1 micron to 300 microns

Size: as the drawing required

Features

Superior Filtration: The cone design maximizes the filtration area, enabling a larger filtration surface compared to other filter shapes. This expanded surface area enhances the filter's capacity to capture and retain particles, resulting in more effective filtration.

Enhanced Mechanical Strength: The sintering process employed in manufacturing the filter significantly enhances its mechanical strength. Sintering involves compacting and bonding the stainless steel particles at high temperatures, creating a solid and robust structure.

Enhanced Diversion: The conical shape allows for better diversion of the fluid or gas flowing through the filter. It promotes a more efficient flow pattern, ensuring that the medium being filtered is evenly distributed across the filter surface.

Versatile Applications: The cone-shaped filter finds wide application in various industries, including chemistry, food processing, beverage, and pharmaceuticals. Its versatility lies in its ability to perform three essential functions—filtering, washing, and drying.

Applications

With regards to water treatment, sintered wire mesh cone filters efficiently remove impurities, sediment, and contaminants from water sources, ensuring clean and purified water for various applications.

In gas filtration within fluidized beds, these filters effectively capture and separate particles, ensuring the optimal performance of the fluidized bed system.

Additionally, their exceptional cleanability makes them ideal for use in sterile product environments, maintaining high levels of cleanliness and hygiene.