Porous Titanium Plates Customized Porosity

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100000pcs/week |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Structure: | Panel Filter |

| Material: | Others |

| Function: | Purification Filter |

| Brand Name: | Toptitech |

| Production Capacity: | 100000pcs/week |

| Packing: | wooden case or carton |

| Delivery Date: | in 10-20 days |

Product Description

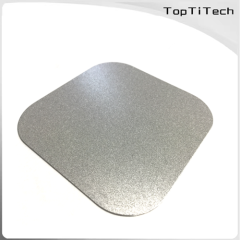

Porous Titanium Plates Customized Porosity

A porous titanium plate is a type of material made from titanium that has many small holes or pores throughout its surface. These pores can range in size from a few micrometers to several millimeters, depending on the manufacturing process and the intended use of the plate.

Porous titanium plates are commonly used in a variety of applications, including biomedical implants, filtration systems, and catalytic converters. One of their most important properties is their high surface area-to-volume ratio, which allows for efficient mass transfer and gas exchange.

Parameters

Material: titanium sponge

Porosity: 35%

Filtration rate: 0.22mm- 100mm

Thickness: above 1mm

Size: square round and customized with the drawing

Features

Versatile pore structure: The pore structure of porous sintered titanium plates can be varied to achieve different properties. For example, plates with a larger pore size may have a higher permeability, while plates with a smaller pore size may have a higher particle retention.

Customized shape and size: Porous sintered titanium plates can be manufactured in a variety of shapes and sizes to suit specific application requirements. This allows for customized designs that can optimize performance and minimize material waste.

Environmental sustainability: Porous sintered titanium plates can be recycled and reused, making them an environmentally sustainable choice. Additionally, the manufacturing process can be optimized to minimize waste and energy consumption.

Applications in energy production: Porous sintered titanium plates can be used in energy production applications such as fuel cells and batteries. The high surface area-to-volume ratio of the plates allows for efficient gas exchange and can enhance the performance of these devices.

Applications

Porous titanium plates are commonly used in a variety of applications, including biomedical implants, filtration systems, and catalytic converters. One of their most important properties is their high surface area-to-volume ratio, which allows for efficient mass transfer and gas exchange.

In biomedical applications, porous titanium plates are often used as bone implants or scaffolds to promote bone regeneration. The porous structure of the plate allows for the growth of new bone tissue into the implant, which can help to repair or replace damaged bones.

In filtration systems, porous titanium plates can be used as a high-performance filter media due to their ability to trap and remove small particles and impurities from fluids.

In biomedical applications, porous titanium plates are often used as bone implants or scaffolds to promote bone regeneration. The porous structure of the plate allows for the growth of new bone tissue into the implant, which can help to repair or replace damaged bones.

How is the porosity of the plate controlled during manufacturing?

The porosity of a porous titanium plate can be controlled during the manufacturing process. In the powder sintering process, titanium powder is compressed and heated to a temperature just below the melting point of titanium. The powder particles then fuse together to form a solid plate with a controlled porosity. The porosity of the plate can be controlled by adjusting the size and shape of the powder particles, the temperature and pressure of the sintering process, and the amount of binder material used.