High Power Carbon Electrodes for Electric Arc Furnace

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 80000 Ton/Year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Graphite Products |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | BENHONG |

| Type: | Electrode Block |

| Length: | 1800mm/2100mm/2400mm/2700mm |

| Resistance (μΩ.m): | ≤5.5 μΩ m |

| Thermal Expansion: | ≤1.5 (10-6/℃) |

| Flexural Strength: | ≥14.5 Mpa |

| Application: | Electric arc furnaces, EAF, ladle furnaces |

| Apparent Density: | ≥1.70 g/cm3 |

| Product Name: | Graphite electrode |

| Function: | Metallurgical steelmaking |

| Transport Package: | Wooden Pallets with Steel Strips |

| Production Capacity: | 80000 Ton/Year |

| Packing: | Graphite Electrodes are packed on wooden pallets |

| Delivery Date: | negotiate |

Product Description

High Power Carbon Electrodes for Electric Arc Furnace

Product Description

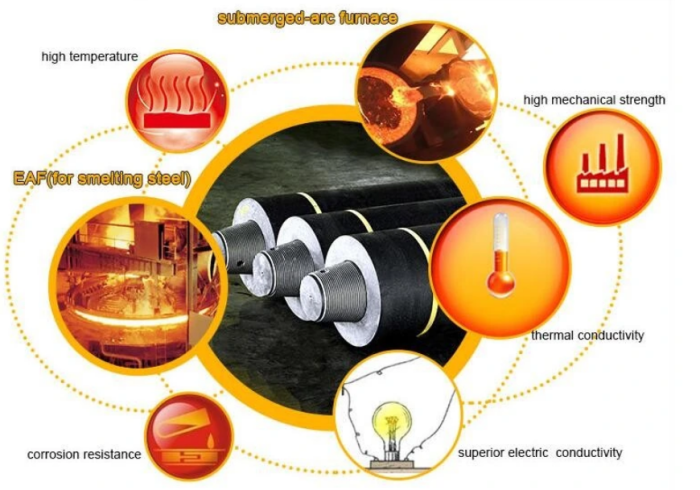

Graphite electrode, mainly from the domestic petroleum BCK and imported needle BCK, is widely used in electric arc furnace,ladle furnace, submerged arc electric furnace for theproduction of alloy steel, metal and

nonmetallic materials.

Our graphite electrodes include regular power, high power, super high power and ultra high power. They are characterized by low resistivity, good electric and thermal conductivity, high resistance to oxidation and thermal shock, high mechanical strength,ect. Our plant offers various dimensions and grades to meet customers' requirements for the specific applications.

Characteristics of graphite electrodes:

1. Low electric resistance

2. Good electricned thermal conductivity

3. High density

4. High anti-oxidation capability

5. High mechanical strength

6. High machining accuracy

Technical Quota of Graphite Electrodes

Item | Unit | RP | HP | UHP | ||

300-800mm | 300-800MM | 300-600MM | 650-800MM | |||

Electric Resistivity ≤ | Electrode | μΩm | 7.8-8.8 | 5.8-6.6 | 4.8-5.8 | 5.8-6.6 |

Nipple | 5.0-9.5 | 4.2-5.0 | 3.8-4.5 | 4.2-5.0 | ||

Flexural strength ≥ | Electrode | Mpa | 7.0-12.0 | 10.0-13.0 | 10.0-14.0 | 10.0-13.0 |

Nipple | 15.0-20.0 | 18.0-22.0 | 20.0-26.0 | 18.0-22.0 | ||

Elastic modulus ≤ | Electrode | Gpa | 7.0-9.3 | 8.0-12.0 | 9.0-13.0 | 8.0-12.0 |

Nipple | 12.0-14.0 | 14.0-16.0 | 15.0-18.0 | 14.0-16.0 | ||

Bulk density ≥ | Electrode | g/cm3 | 1.53-1.56 | 1.62-1.66 | 1.68-1.74 | 1.62-1.66 |

Nipple | 1.70-1.74 | 1.74-1.80 | 1.77-1.82 | 1.74-1.80 | ||

CTE ≤ | Electrode | x10-6/℃ | 2.2-2.6 | 1.6-1.9 | 1.1-1.4 | 1.6-1.9 |

Nipple | 2.0-2.5 | 1.1-1.4 | 0.9-1.2 | 1.1-1.4 | ||

ASH | % | 0.3 | 0.3 | 0.3 | 0.3 | |

Product Advantage:

* Full range of carbon materials, graphite materials, refactories and water treatment materials products and solutions;

* High output, with an annual output of 80,000 tons, timely delivery; guarantee delivery date

* Low resistivity

* High temperature strength

* Good thermal conductivity and electrical conductivity

* Low thermal expansion coefficient

* Low ash,Its ash content is controlled within 3%.

* Dense and equal structure,Low graphite electrode consumption.

* Good oxidation resistance

* High mechanical strength

* Needle BCK content accounts for 80%, raw materials imported from Japan and South Korea

Application:

1. Electric arc steelmaking furnace.

Graphite electrode is mainly used in electric furnace steelmaking. Electric furnace steelmaking uses graphite electrodes to

introduce current into the furnace. A strong current generates an arc discharge through the gas at the lower end of the electrode,

and uses the heat generated by the arc to smelt.

2. Ore-heating furnaces.

Graphite electrode ore-heating furnaces are mainly used to produce ferroalloys, pure silicon, yellow phosphorus, matte and calcium

carbide, etc., which is characterized by electrical conductivity...

3. Resistance furnaces.

Graphitization furnaces for producing graphite products, melting furnaces for melting glass, and electric furnaces for producing

silicon carbide are all resistance furnaces.

4. Used for processing.

A large number of graphite electrode blanks; also used for processing into various crucibles, graphite boats, hot die casting

molds and heating elements for vacuum electric furnaces, etc...

Packing & Delivery

normally our package is neutral standard export wooden support with twining plastic bags , to protect the all goods always are perfect when arriving clients' warehouse, no damage and no dirty during shipment .

FAQ

Q1.You are fractory manufacturer or trader?

A1: Manufacturer, some time we help our clients to purchase relevant products as a trader.

Q2: What's the MOQ?

A2. No limitation.

Q3: Can we visit your factory?

A3: Of course ,welcome at any time,seeing is believing

Q4: What's your payment terms?

A4: Negotiation

Q5: Is your company accept customization?

A5: Professional technology teams and engineers all can satisfy you.

Q6: How do you guarantee quality?

A6: For every production processing,we have complete QC system for the chemical composition and Physical properties.After

production,all the goods will be tested ,and the quality certificate will be shipped along with goods.

Q7: What's the proportion of abroad business?

A7: Abroad market around 35%; Domestic market around 65%; and now export proportion is increasing.