Hot selling of graphite electrode for electric arc furnace

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 80000 Ton/Year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Graphite Products |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | BENHONG |

| Model NO.: | 500mm*2400mm |

| Application: | Steel Making |

| Nipple: | 4 Tpi |

| Specification: | 300mm-700mm |

| Bulk Density: | 1.72 |

| Ash: | 0.3% |

| Resistivity: | 5.5 |

| keywords: | graphite electrode rp hp uhp |

| Carbon Content: | High-Carbon |

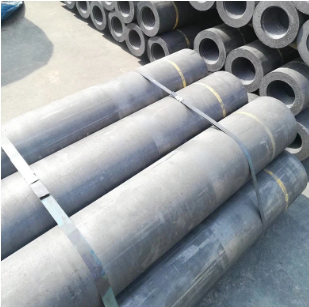

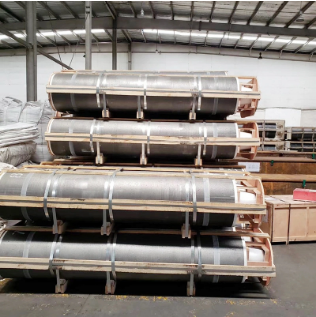

| Transport Package: | Wooden Pallets with Steel Strips |

| Production Capacity: | 80000 Ton/Year |

| Packing: | Graphite Electrodes are packed on wooden pallets |

| Delivery Date: | negotiate |

Product Description

Product Description

Manufacturer and dealer of graphite and carbon products. We have been in graphite and carbon industry for more than 30 years, we gained superior knowledge of graphite and carbon products.The strong and stable network we have enables us to offer you a competitive price. Our competent manufacturing and sale team are well trained to recommend you optimum products based on your individual requirements. Specialized colleagues provide professional support in logistics and transport.

Why do leading graphite producers choose us as a preferred partner?

GES Asia-Pacific could gain an outstanding reputation through its devotionto stable and long-term oriented relationships. Through our passion for the business, We could become a proud member of a network of famouscarbon and graphite manufacturers in China. Our goal is to pass on to youthis advantage and build with you a trustworthy and long-lasting business relationship.Our experienced staff looks forward to assisting you with efficient service!

Specifications:

| Technical Indicators | Bulk Density g/cm3 | Resitivity μΩ·m | Bending Strength Mpa | ||||

| Electrode | Nipple | Electrode | Nipple | Electrode | Nipple | ||

| RP | 200-450mm | 1.54-1.62 | 1.73-1.78 | 7.0-8.8 | 4.2-5.2 | 7.5-9.5 | 17-22 |

| 500-700mm | 7.5-9.5 | 6.5-8.5 | |||||

| HD | 200-450mm | 1.64-1.72 | 1.75-1.80 | 5.4-6.6 | 3.8-4.8 | 10.0-15.0 | 19-24 |

| 500-700mm | 5.8-7.3 | 10.0-15.0 | |||||

| HP | 200-450mm | 1.65-1.73 | 1.77-1.82 | 5.0-6.2 | 3.4-4.4 | 10.5-15.5 | 21-26 |

| 500-700mm | 5.3-6.5 | 10.0-15.0 | |||||

| UHP | 300-450mm | 1.66-1.74 | 1.80-1.86 | 4.2-5.8 | 3.0-4.0 | 10.5-15.5 | 23-32 |

Guidance of Using

Being hard and brittle ,artificialgraphite electrode shall be specially handled.Proper operationg may reduce the consumption and cost.

1. Professional tools should be used for hoisting graphite electrodes. It is strictly forbidden to use a crowbar to prevent impact damage during handling.

2. Graphite electrodes are prohibited from rain, snow and water, and should be kept dry. If it is found to be damp, it should be dried before use, the temperature should not exceed 100 ºC, and the drying time should not be less than 48h.

3. Do not stack near debris such as clay, slag, etc., so as not to pollute the surface of the graphite electrode and affect the conductive effect.

4. Before the graphite electrode is connected, carefully check whether the electrode connector hole is intact, whether the connector thread is damaged, and whether the connector bolt is lost. When the electrode is lifted, the electrode connector thread of the ground terminal should be prevented from being damaged.

5. Dust and debris in the joints and joint holes should be blown dry with compressed air.

6. Graphite electrodes must be tightly connected, and no tilt is allowed during connection. Torque wrenches should be used to prevent excessive force or too small, and the gap is not greater than 0.4mm.

7. The electrode holder should be clamped, not loose and in good contact, and no arc should be generated. Otherwise, the connection will be reddish, oxidized, thinned and broken.

8. If the electrode is lifted with a metal lifting plug, the thread in the joint hole must not be damaged. After lifting, the lifting plug should be unscrewed to prevent dust and debris from falling into the joint hole.

9. When the electrode lifting device of the electric furnace is running, it should be kept stable. After the furnace cover is repaired, check whether the furnace cover is positioned correctly. During smelting, refractory materials are used to close the furnace lid to prevent the oxidation of the upper electrode of the flame in the furnace.

10. The holder should be clamped outside the safety wire of the electrode connector hole area.

11. When distributing the molten pool, the big piece is at the bottom and the small piece is at the top. Do not place the charge with poor conductivity on the top. During melting, the unmelted charge should be handled in time to prevent the collapsed material from breaking the electrode.

Company

Packaging & Shipping

our graphite electrode package:

normally our package is neutral standard export wooden support with twining plastic bags , to protect the all goods always are perfect when arriving clients' warehouse, no damage and no dirty during shipment .

FAQ

1.When can I get the price?

We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order, you

can call us directly.

2. What is your terms of delivery?

We accept FOB,CFR,CIF,EXW,etc.You can choose the most convenient way for you.Besides that,we can also shipping by Air and Express.

3.Product packaging?

We are packed in wooden cases, or according to your requirements.

4.What's the dellivery?

The lead time is based on the quantity, about 10-15 days. For graphite product, apply Dual-use items license need about 15-20 working days.

5. Notice

Please note that the price on alibaba is a rough price.The actual price will depends on raw materials, exchange rate ,wage and your order quantity