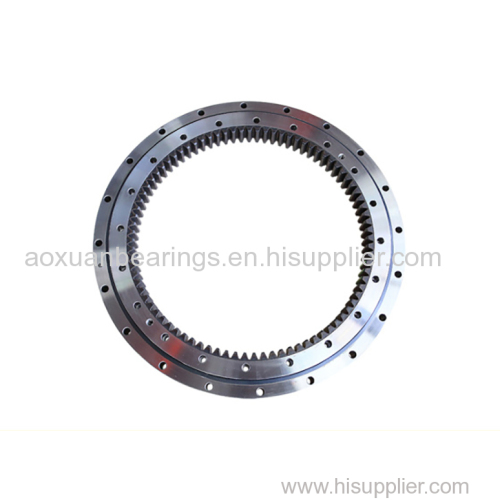

Slewing Bearing Gear Ring Slewing Ring For SUMITOMO SH60 Excavator

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20000sets per year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Changzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 764*564*96 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | AOXUAN |

| inner ring size: | 564mm |

| outer ring size: | 764mm |

| Thickness: | 96mm |

| Goods offer: | OEM |

| Material: | 50Mn |

| Production Capacity: | 20000sets per year |

| Packing: | wooden Box |

| Delivery Date: | 7-45days |

Product Description

SLEWING BEARING RING:

QNA683.22.Z1, QNA683.22.Z14, QND1087.22.Z2, QND1087.22.Z3, QND1087.22.Z8, QND1227.28.Z4, QND1225.28.Z5, QND1260.32.Z7, QND1215.28.Z9, QND1343.35.Z13, QND1360.38.Z12, QND1360.38.Z10, QND1450.40.Z11

SLEWING RING FOR:

SUMITOMO SH60A1,SUMITOMO SH60-1,SUMITOMO SH120A1/JS140,SUMITOMO SH120A3,SUMITOMO SH265/SH260,SUMITOMO SH350/SH300A1,SUMITOMO SH200A1b/SH200A2,SUMITOMO SH200A3,SH220-2,SUMITOMO SH280,SUMITOMO SH430,SUMITOMO SH300A2,SUMITOMO SH300-3

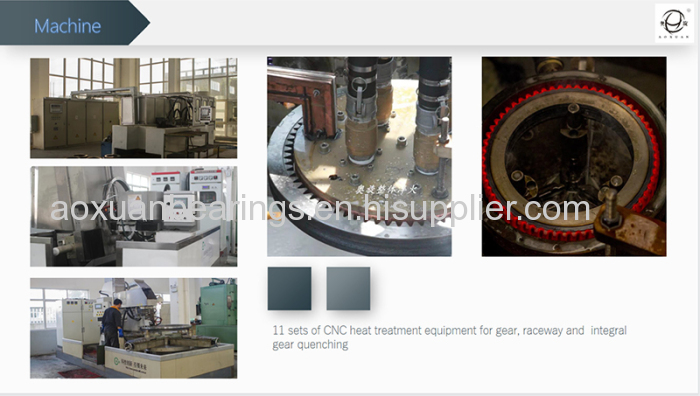

Aoxuan Heavy Bearing has passed ISO9001: 2015 quality management system certification and EU CE certification, and has been recognized as a high-tech enterprise in Jiangsu Province, a private technology enterprise in Changzhou and a heavy-duty slewing bearing engineering technology research center in Changzhou. The company has 2 invention patent certificates, 20 utility model patent certificates, and 4 computer software copyright registration certificates, which are increasing year by year.

Order process: 1. Consulting customer service; 2. Specifying requirements; 3. Drawing confirmation; 4. Signing contracts; 5. Arranging production; 6. Warehouse shipment; 7. Confirming receipt.

Normally, goods will be delivered within 3-7 days from stock, 25-35 days from no stock, and about 45 days for customized products. Welcome to inquire.

The pictures are for reference only, and the price is subject to the contract. Please contact the customer service to confirm the model, specification, size and process requirements of the product. For the same specification, there may be differences in installation holes, quenching and other processes, so the confirmation of drawings is to ensure that the products are what you need, and the signing of contracts is to protect your rights and interests.

Slewing bearing is also known as rotary bearing and slewing bearing. Slewing bearing is widely used in real industry and is called "machine joint" by people. It is an important transmission component for machinery that needs to make relative rotary motion between two objects, and also needs to bear axial force, radial force and tipping torque. Its main role is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotary accuracy. The rotation speed of slewing ring is lower than that of general bearings.

According to the different friction properties of moving elements, slewing bearings can be divided into rolling bearings and sliding bearings. The rolling bearing has been standardized and serialized, but compared with the sliding bearing, its radial size, vibration and noise are larger, and its price is higher. Its basic structure is generally composed of four parts: outer ring, inner ring, rolling element and cage. According to the shape of rolling element, rolling bearings are divided into ball bearings and roller bearings.

The application of this type of bearing is common in the structural composition of large construction machinery, such as earthwork machinery, excavator, stacker reclaimer, grader, roller, rock drilling machinery, roadheader, etc. Others include concrete machinery, hoisting machinery, engineering ships, aerial work platforms, etc.

In addition to various engineering machinery, the application scope of slewing ring has been gradually expanded. At present, similar equipment platforms such as port equipment, metallurgical equipment, wind power generation equipment, drilling platforms, etc. have begun to use slewing ring to replace the original bearing in a large range. In practical application, the specification, size, accuracy and other conditions of the bearing shall be selected according to the use position, use conditions and environment of the bearing. The suitable bearing can effectively ensure the life of the slewing ring, which is the premise of the life and feasibility of the slewing ring.