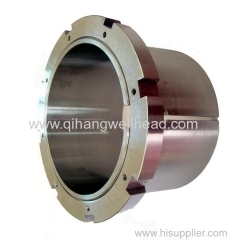

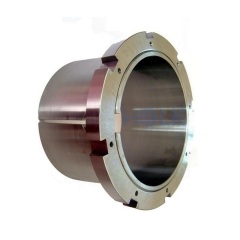

H39 (H3900) Series Bearing Adapter Sleeves

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF,FCA,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 100000 pcs/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Yancheng, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Service |

Product Detail

| Model No.: | H3952 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | HOLK |

| Product Name: | Bearing Adapter Sleeves |

| Series: | H39 Series, H3900 Series |

| Material: | 20# Steel |

| Taper: | 1:12 |

| Surface Treatment: | Anti-Rust Oil |

| Surface Roughness: | Below Ra 2.5 |

| Packaging: | Neutral Packing |

| Applications: | Locating bearings with a tapered bore onto a cylindrical seat |

| Production Capacity: | 100000 pcs/month |

| Packing: | Neutral Carton Packaging |

| Delivery Date: | 30 days |

Product Description

Bearing Adapter Sleeves are commonly used for locating bearings with a tapered bore onto a cylindrical seat as they can be used on plain or stepped shafts. They are easy to install and require no additional location on the shaft. When adapter sleeves are used on plain shafts, the bearing can be located at any position on the shaft. When used on stepped shafts together with an L-shaped spacer ring, bearings can be accurately positioned axially thereby facilitating bearing mounting and dismounting.

Adapter sleeves with hydraulic assistance (Hydraulic Adapter Sleeves) facilitates mounting of large bearings. Oil pumps are required to inject pressurized oil. They are provided with oil ducts on the thread side and groove on the outer surface for oil injection internal upon request, facilitating the mounting and mainly the dismounting of the assembly.

The hydraulic adapter sleeve has the characteristics of prolonging the life of the bearing and protecting the bearing. It can be used in steel construction, cement mining, textile industry etc.

HOLK Bearing has more than 20 years of experience in the production of high-quality both European Metric and American Inch Standard Power Transmission products.

We manufacture premium quality Bearing Adapter Sleeves worth more than US$500,000 to a big famous European bearing company every year.

We produce top-notch quality Split Plummer Blocks worth more than US$1,000,000 to a big famous European bearing company every year.

Our Adapter Sleeves range covers H 2 series, H 3 series, H 23 series, H 30 series, H 31 series, H 32 series, H 39 series, and Hydraulic Adapter Sleeves of HOH 23/HOH32 series, HOH 31 series, HOH 30 series, and HOH 39 series.

The Withdrawal Sleeves range covers AH 2 series, AH 3 series, AH 23 series, AH 32 series, AH 22 series, AH 30 series, AH 240 series, AH 241 series, and AH 39 series, and Hydraulic Withdrawal Sleeves of AOH 22 series, AOH 23 series, AOH 30 series, AOH 31 series, AOH 32 series, AOH 39 series, AOH 240 series and AOH 241 series, etc.

Technical Details:

Product Name: Bearing Adapter Sleeves

Series: H 39 series, H 3900 series

Taper: 1:12

Roughness: below Ra 2.5

Material: Carbon Steel

Surface Treatment: Anti-Rust oil; Blackening is available upon request

Packaging: Neutral, customized packaging is also available

Our adapter sleeves are supplied complete with Lock Nuts and Lock Washers. Both Metric and Inch adapter sleeves are available.

Drawing and Technical Data Sheet of H39 (H3900) series Adapter Sleeves

| Adapter Sleeves No. | d1 | d | G | l | Dm | P | Lock Nuts + Locking Device | Bearings |

| mm | mm | mm | mm | mm | ||||

| H 3924 | 110 mm | 120 | M 120x2 | 60 | 145 | KML 24 + MBL 24 | 23924K | |

| H 3926 | 115 mm | 130 | M 130x2 | 65 | 155 | KML 26 + MBL 26 | 23926K | |

| H 3928 | 125 mm | 140 | M 140x2 | 66 | 165 | KML 28 + MBL 28 | 23928K | |

| H 3930 | 135 mm | 150 | M 150x2 | 76 | 180 | KML 30 + MBL 30 | 23930K | |

| H 3932 | 140 mm | 160 | M 160x3 | 78 | 190 | KML 32 + MBL 32 | 23932K | |

| H 3934 | 150 mm | 170 | M 170x3 | 79 | 200 | KML 34 + MBL 34 | 23934K | |

| H 3936 | 160 mm | 180 | M 180x3 | 87 | 210 | KML 36 + MBL 36 | 23936K | |

| H 3938 | 170 mm | 190 | M 190x3 | 89 | 220 | KML 38 + MBL 38 | 23938K | |

| H 3940 | 180 mm | 200 | M 200x3 | 98 | 240 | KML 40 + MBL 40 | 23940K | |

| H 3944 | 200 mm | 220 | Tr 220x4 | 96 | 260 | HM 3044 + MS 3044 | 23944K | |

| H 3948 | 220 mm | 240 | Tr 240x4 | 101 | 290 | HM 3048 + MS 3048-MS 3052 | 23948K | |

| H 3952 | 240 mm | 260 | Tr 260x4 | 116 | 310 | HM 3052 + MS 3048-MS 3052 | 23952K | |

| H 3956 | 260 mm | 280 | Tr 280x4 | 121 | 330 | HM 3056 + MS 3056 | 23956K | |

| H 3960 | 280 mm | 300 | Tr 300x4 | 140 | 360 | HM 3060 + MS 3060 | 23960K | |

| H 3964 | 300 mm | 320 | Tr 320x5 | 140 | 380 | HM 3064 + MS 3064-MS 3068 | 23964K | |

| H 3968 | 320 mm | 340 | Tr 340x5 | 144 | 400 | HM 3068 + MS 3064-MS 3068 | 23968K | |

| H 3972 | 340 mm | 360 | Tr 360x5 | 144 | 420 | HM 3072 + MS 3072 | 23972K | |

| H 3976 | 360 mm | 380 | Tr 380x5 | 164 | 450 | HM 3076 + MS 3076-MS 3080 | 23976K, C 3976K | |

| H 3980 | 380 mm | 400 | Tr 400x5 | 168 | 470 | HM 3080 + MS 3076-MS 3080 | 23980K | |

| H 3984 | 400 mm | 420 | Tr 420x5 | 168 | 490 | HM 3084 + MS 3084 | 23984K | |

| H 3988 | 410 mm | 440 | Tr 440x5 | 189 | 520 | HM 3088 + MS 3088-MS 3092 | 23988K | |

| H 3992 | 430 mm | 460 | Tr 460x5 | 189 | 540 | HM 3092 + MS 3088-MS 3092 | 23992K | |

| H 3996 | 450 mm | 480 | Tr 480x5 | 200 | 560 | HM 3096 + MS 3096-30/500 | 23996K, C 3996K | |

| H 39/500 | 470 mm | 500 | Tr 500x5 | 208 | 580 | HM 30/500 + MS 3096-30/500 | 239/500K | |

| H 39/530 | 500 mm | 530 | Tr 530x6 | 216 | 630 | HM 30/530 + MS 30/530-600 | 239/530K | |

| H 39/560 | 530 mm | 560 | Tr 560x6 | 227 | 650 | HM 30/560 + MS 30/560 | 239/560K | |

| H 39/600 | 560 mm | 600 | Tr 600x6 | 239 | 700 | HM 30/600 + MS 30/530-600 | 239/600K | |

| H 39/630 | 600 mm | 630 | Tr 630x6 | 254 | 730 | HM 30/630 + MS 30/630 | 239/630K | |

| H 39/670 | 630 mm | 670 | Tr 670x6 | 264 | 780 | HM 30/670 + MS 30/670 | 239/670K, C 39/670K | |

| H 39/710 | 670 mm | 710 | Tr 710x7 | 286 | 830 | HM 30/710 + MS 30/710 | 239/710K | |

| H 39/750 | 710 mm | 750 | Tr 750x7 | 291 | 870 | HM 30/750 + MS 30/750-800 | 239/750K | |

| H 39/800 | 750 mm | 800 | Tr 800x7 | 303 | 920 | HM 30/800 + MS 30/750-800 | 239/800K | |

| H 39/850 | 800 mm | 850 | Tr 850x7 | 308 | 980 | HM 30/850 + MS 30/850-900 | 239/850K | |

| H 39/900 | 850 mm | 900 | Tr 900x7 | 326 | 1030 | HM 30/900 + MS 30/850-900 | 239/900K | |

| H 39/950 | 900 mm | 950 | Tr 950x8 | 344 | 1080 | HM 30/950 + MS 30/950 | 239/950K | |

| H 39/1000 | 950 mm | 1000 | Tr 1000x8 | 358 | 1140 | HM 30/1000 + MS 30/1000 | 239/1000K | |

| H 39/1060 | 1000 mm | 1060 | Tr 1060x8 | 372 | 1200 | HM 30/1060 + MS 30/1000 | 239/1060K | |

| H 39/1120 | 1060 mm | 1120 | Tr 1120x8 | 372 | 1260 | HM 30/1120 + MS 30/1000 | 239/1120K |

Great care has been taken to ensure the correctness of the information contained in this publication but no liability can be assumed for any incorrect or incomplete data. The HOLK technical department reserves the right to final interpretation.

The roughness of HOLK's adapter sleeves and withdrawal sleeves is generally below Ra. 2.5.

HOLK's adapter sleeves and withdrawal sleeves are supplied with anti-rust oil on the surfaces. Blackening is available upon request.