Laser Taper Measuring Instrument (Multi-dimensional Detection)

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Place of Origin: | Hubei |

Company Profile

| Location: | Wuhan, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | MDC-L200 |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

Product Description

MDC-L200 Laser Taper Measuring Instrument (Multi-dimensional Detection)

Overview:

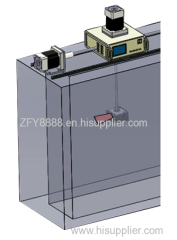

Laser taper measuring instrument (multi-dimensional detection) is a new type of mold multi-taper measuring instrument developed by our company. The instrument adopts a high-precision, high-sensitivity laser measurement and positioning sensor, which scans the copper plate of the mold by a fixed-width laser line, and returns the measurement data in real time. The host computer shows the data of mold taper, surface cracks, surface flatness and other data after modeling and analyzing the returned measurement data. The upper computer software intuitively reflects the situation of the multi-taper surface of the tested mold to the user in the form of data table, data curve and 3D model diagram of the mold taper, and provides a true and reliable theoretical basis for the on-site operators to maintain the mold.

The measurement principle:

The mold multi-taper measuring instrument is a high-precision instrument. The whole instrument includes a high-precision laser ranging sensor, two digital servo motors, an encoder, a horizontal sliding screw, a vertical sliding screw, and a calibration console and controller etc. The equipment has many advantages such as high measurement accuracy, strong stability, easy installation and strong observability. The instrument is suitable for the multi-taper detection, surface flatness analysis and surface flaw detection of continuous casting molds in the continuous casting process of major iron and steel enterprises. It is suitable for round billets, square billets, slabs, etc., widely used and powerful. When measuring the multi-taper characteristics of the mold, the instrument is fixed on the top of the mold as shown in Figure 1. After the equipment is started, the self-inspection process is automatically completed, and the laser measuring sensor automatically returns to the initial zero position, and then the laser sensor scans along the inner surface of the mold under the drive of the digital servo motor, and then the laser sensor descends to a certain height to continue scanning for a circle. The entire inner surface of mold is repeatedly scanned from top to bottom. After the scanning is completed, the data is transmitted to the host computer through wireless communication or wired communication. The host computer software imports the collected data into the model base, and obtains the multi-taper status, surface flatness, cracks and other situation of the mold through calculation and analysis, which provide reliable maintenance reference data for on-site production and avoid production accidents on site due to the equipment failure.

The features:

Humanized human-computer interaction interface

Convenient system settings

Portable low power consumption design

Compatible detection structure with lots of specifications

High-speed and stable wireless data transmission

High-precision laser scanning measurement

One-click measurement design

Own network wireless transmission

Small and lightweight front-end measurement

The parameters:

Mold width range: 60~400mm

Measurement accuracy: 0.01mm

Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan)

Measurement method: laser displacement measurement

Measuring beam: 3200 points

Movement mode: high precision servo

Movement accuracy: 1mm/65536 pulses

Single measurement time: less than 2min

Power supply: DC12V

Operating temperature: -20~80℃

Shock resistance: 50G (X, Y, Z axis)