ZT Metal steel door frame making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 Set/Sets per Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 2022-2 |

|---|---|

| Means of Transport: | Ocean |

| Raw Material: | Sheet / Plate Rolling |

| Power: | Hydraulic |

| Machine Type: | Roll Forming Machine |

| Automation: | Automatic |

| Extra Services: | Machining |

| Material / Metal Processed: | Stainless Steel |

| Certification: | ISO 9001:2000 |

| Brand Name: | Zhongtuo |

| Production Capacity: | 20 Set/Sets per Month |

| Packing: | Tianjin new port |

| Delivery Date: | 65 |

Product Description

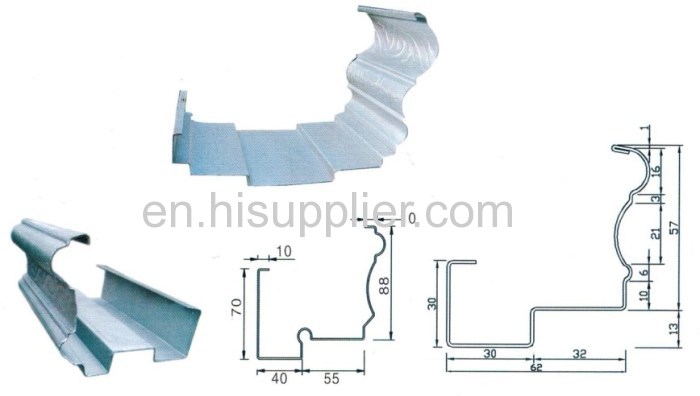

the basic Information of door frame roll former machinery

Processing material: colored steel plate, galvanized plate, or aluminium plate Material thickness: 0.8---1.5 mm Material hardness: 550 mpa---350 mpa Material width: 200mm(according to the profile) Formed width: 101.6mm (according to the profile) Forming speed: 12m/min Working speed :8m/min |

Uncoiler System

| Usage:It is used to support the steel coil and uncoil it in a turnable way. Passive uncoil pulled by roll forming system |

Loading capacity:1.5T

Uncoiling width:400mm

Inner diameter: 450-508mm |

Main Roll Forming System of door frame roll former machinery

| Feature : Ensure stability , precision and lifetime. |

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller surfaces polishing, hard plating,heat treatment and galvanized treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. | |

Length of the main part: about 3500*900*1000 Weight of main part: 3 tons Voltage : 380V 50HZ 3Phase | |

Roller fixer : Guide column Frame : 400 H steel Drive mode: chain | |

Material of rollers:45# steel, surface hard chromium plating. Material of shafts: 45# steel with tempering Diameter of shafts: φ70mm Number of rollers : 20 rollers Main power: 5.5kw(cycloidal planetary gear speed reducer) Hydraulic power : 3kw |

Shearing Mechanism

| Feature : Ensure stability, precision and cutting speed Function : Automatic cutting controlled by PLC |

It adopts the hydraulic drive and automatic location to decide the dimention and cut the target products. | |

Material of blades: Gcr12 quenched Power supply : hydraulic power Frame : Pillar style with rack & pinion systme Stroke switch : non-contact photoelectric switch | |

Components:It contains one set of cutting tools, one hydraulic tank and one cutter machine.

|

final production(as a reference)

Our Services

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest

70% of the total contract value to be paid by T/T after inspection by buyer in seller's factory while before delivery.

Service: we sent technician to your country to fix the machine.

The buyer should bear all the cost including: visa , Roundtrip ticket and suitable

accommodation, also buyer should pay the salary 100USD/day.

Warranty: 12 months limited warranty

During warranty, parts are free but buyer pay for the shipping fee

Period of validity: 30 days