High speed light keel metal steel CD UD stud track double line roll former

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Set/Sets per Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 2022 |

|---|---|

| Means of Transport: | Ocean |

| Raw Material: | Sheet / Plate Rolling |

| Power: | Cnc |

| Machine Type: | Others |

| Automation: | Automatic |

| Extra Services: | Others |

| Material / Metal Processed: | Stainless Steel |

| Certification: | ISO 9001:2000 |

| Brand Name: | Zhongtuo |

| Warranty of core components:: | 1 Year |

| Control system:: | PLC(Touch Screen) |

| Production Capacity: | 30 Set/Sets per Month |

| Packing: | One 40ft container |

| Delivery Date: | 25 |

Product Description

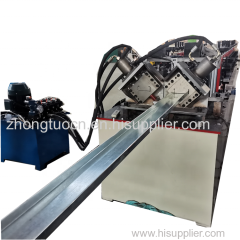

The specification of stud track double line roll former technical parameters:

| No | Series | Parameter |

| 1 | Machine structure | Vertical arch frame sturcture |

| 2 | Voltage | 380V-50HZ-3P or as your required |

| 3 | Roller material | Cr12 |

| 4 | Roller shaft material | 45#steel with quenched treatment |

| 5 | Roller station | 12 stations or according to profile |

| 6 | Drive type | By chains drive |

| 7 | Cutter material | Cr12 |

| 8 | Cutting type | Hydraulic cutting |

| 9 | PLC brand | Delta or as your required |

| 10 | Frequency brand | Delta or as your reqiured |

| 11 | Machine weight | 4.5 Tons |

| 12 | Main power | 15 KW |

| 13 | Work speed | 25m/min or 40m/min as your request |

There are some photos about the stud track roll former we have sold as below:

We use double head manual decoiler, each head has 1.5 Tons loading capacity.

The decoiler structurer is stable and strong, easy operate and easy loading the coil.

And have break system to better control the decoiler stopping.

The stud track double line roll former has two production line.

The left side and right side use one machine structure to save much costs and space.

Each side max speed can reach 40 m/min.

Our machine use iron casting vertical frame to ensure when the machine running in a high speed will very stable.

In the cutting system, each production has a servo motor to make ensure the cutting system is stable running in high speed.