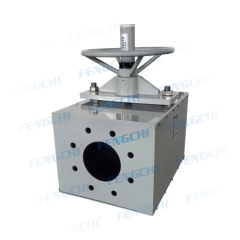

Manual & Electric Pinch Valves

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T |

| Supply Ability: | 10000 |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | FCE001 |

|---|---|

| Means of Transport: | Ocean |

| Technique: | Others |

| Surface Treatment: | Coated |

| Type: | Others |

| Steel Grade: | FengChi |

| Thickness: | As request |

| Production Capacity: | 10000 |

| Packing: | Non-Fumigation Wooden Box |

| Delivery Date: | 30 Working Days |

Product Description

Technical specification

Size range: 15~2000mm, ½~84in

Pressure range: 1-10MPa, 1:2 safety factor, which means bursting pressure is 2 times higher than the operating pressure.

Material of valve body

DN15~200 (carbon steel, ductile iron, aluminum alloy, stainless steel-casting process)

DN250~2000 (45#steel, stainless steel welding technology )

Material of valve sleeve: NR, EPDM, CR(chloroprene rubber), NBR, butyl rubber, FPM, Hypalon rubber.

Working status of pinch valve

Fully-open: the full-bore elastic valve sleeve of pinch valve without any gaps & dead spots.

Center closed: closed on the center line of the valve body, which avoids turbulence and abrasion, as a result, the valve sleeve becomes a smooth and enclosed venturi with self-cleaning during every operation.

Fully-closed: it ensures the pinch valve is with no leakage of two ways when shut off, and the safe design of inner valve sleeve requires no maintenance of sealing elements.