Forged AISI 4340 Steel High Quality Manufacturer Suppliers

| Min. Order: | 1 Ton |

|---|---|

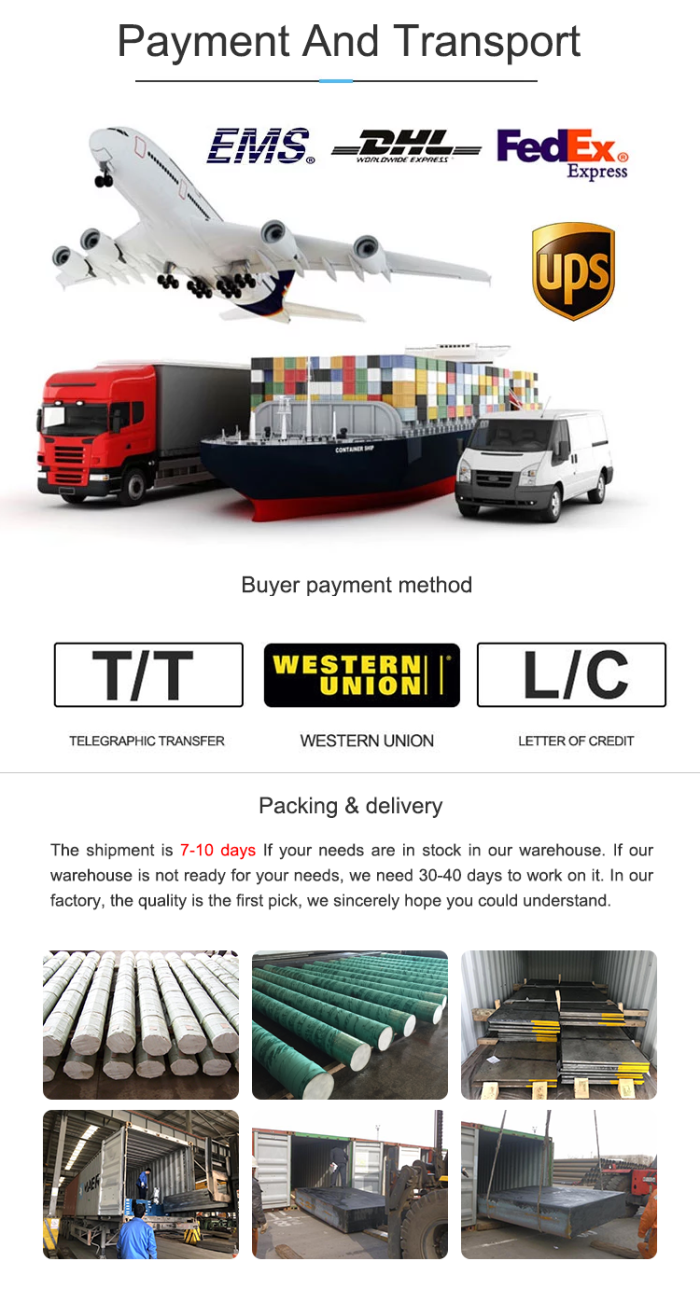

| Trade Term: | FOB, |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10000 Ton/Tons per Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 36CrNiMo4 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Model No.: | 4340/1.6511/SNCM439/40CrNiMoA |

| keywork: | 4340 steel suppliers,forged 4340 steel |

| Technology: | Hot Rolled/Forged/Clod Draw |

| Heat treatment: | Annealing Q+T |

| Surface condition: | Black/Peeled / Machined/Grind |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching |

| Experience: | 10 Years Of Manufacture Experience |

| website: | https://steelpurchase.com/,http://www.songshunsteel.com/index.html |

| Skype/Whatsapp/Wechat: | 86-13723516041 |

| Contact E-mail: | jacklu@songshunsteel.com |

| Production Capacity: | 10000 Ton/Tons per Month |

| Packing: | seaworthy packing |

| Delivery Date: | 15-45 days |

Product Description

AISI/ASTM 4340 belongs to the American standard high-strength alloy structural steel, which is made of high-quality carbon structural steel

by appropriately adding one or more alloying elements (the total content does not exceed 5%). AISI 4340 is also one kind of nickel

chromium molybdenum steels.It will get high strength after the heat treat. And it has good toughness, fatigue resistance, impact

toughness and etc. 4340 steel round bar sheet plate will get high tensile strength, hardness and toughness after heat treatment.

It is used widely in the transmission components of heavy chemical machinery. Different sections of each part of the casting which

cause the temperature difference stress and phase transformation stress.

1.Product Details

· keyword:4340 steel suppliers,forged 4340 steel

· Usage: It is used as important quenched and tempered parts that require good toughness,high strength and large size,

such as heavy machinery and high-load shafts,turbine shafts with a diameter greater than 250mm, helicopter rotor shafts,

turbojet engine turbine shafts,blades, high Loaded transmission parts, crankshaft fasteners. gears, etc.;

· Other Steel Types:5140 /4140 / 4340 / 4142 / 15CrMo / 6150 / 38CrMoAI / 8620 .....

· Serve:OEM/ODM

· Delivery status:With heat treatment (normalized, annealed or high temperature tempered) or without heat treatment Goods, the delivery status should be specified in the contract

2. 4340 Steel Equivalent Steel Grade

China GB steel number40CrNiMoA, German DIN steel number 36CrNiMo4, German DIN material number 1.6511,

French NF standard 40NCD3, Japanese JIS standard SNCM439, British BS standard 816M40, American AISI/ASTM4340,

American UNS standard G43400

3. AISI 4340 Chemical composition

| C | 0.38-0.43% | Cr | 0.70-0.90% |

| Si | 0.15-0.35% | Mo | 0.20-0.30% |

| Mn | 0.30-0.80% | Ni | 1.65-2.00% |

| P | ≤0.025% | S | ≤0.025% |

4. SAE 4340 Mechanical Properties

Tensile Strength | σb (MPa):≥900(100) |

| Yield Strength | σS (MPa):≥835(85) |

| Elongation | δ5 (%):≥12 |

| Reduction | ψ (%):≥55 |

| Impact Energy | Akv (J):≥78 |

| Impact Toughness | akv (J/cm2):≥98(10) |

| Annealed Hardness | ≤269HB |

5. ASTM 4340 Surface Treatment and Heat Treatment

1.Surface Treatment

Plate: Origin Black, Orign cold rolled bright, Machined, Grinded

Bar: Origin Black, Orign cold rolled(drawn) bright, Turned, Peeled, Grinded

2.Heat treatment specification

Quenching at 850℃, oil cooling; tempering at 600℃, water cooling, oil cooling

The Brinell hardness GBW of steel in annealed or high temperature tempered supply

state is less than or equal to 269;

4340 steel offers toughness and high strength inthe heat treated condition,

with in round bar 4340 is available fully certified and suitable for applications

requiring a quality tensile alloy steel.AISI 4340 is commonly supplied quenched

and tempered with a hardness of between 24 to 29HRc.

6.4340 Steel Applications

It is used as important quenched and tempered parts that require good toughness, high strength and large size, such as

heavy machinery and high-load shafts, turbine shafts with a diameter greater than 250mm, helicopter rotor shafts, turbojet

engine turbine shafts, blades, high Loaded transmission parts, crankshaft fasteners. Gears, etc.; can also be used for rotor

shafts and blades whose operating temperature exceeds 400 °C; can also be used to manufacture important parts with special

performance requirements after nitriding treatment, and can be used for ultra-high temperature after low temperature tempering

or austempering. Use of strength steel

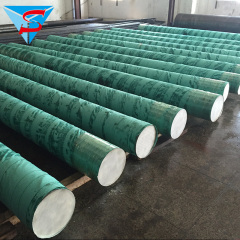

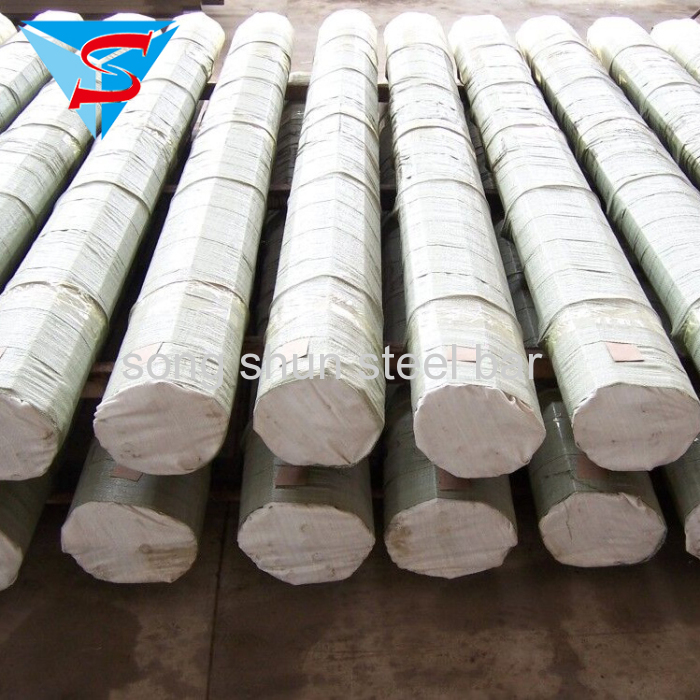

7.G43400 Steel Product Photo

8.Company Introduction

Dongguan Songshun Mould Steel Co., Ltd. is an Indusrtial and trading company with 2 warehouses that manufactures good & high

quality kinds of steels starting from 2012. The company provides the customized products and OEM service. What´s more, we keep the

mass stock of over 20000 tons. In those years, we offer a wide range of steels to our customers from all over the world. And we enjoy

high praise among them.

9.Customer Photos

We warmly welcome new and old customers to establish good and long term relationship with us based on equality and mutual assistance.

10.Certifications

11.Product packaging

12.FAQ

Q:Are you a factory or a trading company?

A: The fact is that we are a company. We have own factory and several warehouses. Under the trend of globalization of the world, we established a professional foreign trade department to change the world.

Q: What is your delivery date?

A: The delivery date is about 10-30 days after receipt of payment.

Q: Can I get some samples?

A: We are honored to offer you samples.

Q: What port do you usually ship from?

A: We have 3 common ports,Tianjin, Shanghai and Shen.

Q: What is the payment terms?

A: T/T is our priority, L/C is also OK for us.

13.Contact us

Feel free to contact us,we are glad to serve for you.

Songshun Always Open the Door for You.

MiKi Zhuo

Skype/Whatsapp/Wechat:86-13723516041

ADD:No.4 Dongda Street, Shatou, Changan Town, Dongguan City, Guangdong Province, P.R.C China