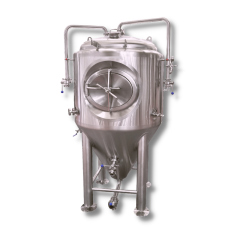

Beer fermentation tank unitank fermenters 500l 1000l 2000l

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 200L-5000L per batch |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Processing Types: | Others |

| Processing: | Others |

| Brand Name: | SENMO |

| Application: | Beer production |

| Use for: | Brewery |

| Material: | Stainless steel 304 |

| Control: | Semi-automatic |

| Heating: | Steam/fire/Electric tubes |

| Cooling: | Cooling jacket |

| Capacity: | 200-5000L |

| Customized design: | Yes |

| After service: | Yes |

| Power: | Customzed |

| Production Capacity: | 200L-5000L per batch |

| Packing: | Iron frame |

| Delivery Date: | 70 days |

Product Description

Beer fermentation tank unitank fermenters 500l 1000l 2000l

Fermenter are also called CCT's (Cylindrical Conical Tanks), FV's (Fermentation Vessel), primary fermentor or unitanks as they are used both for fermenting and lagering. Fermenting is the process during which the yeast transforms the wort into beer. Lagerings takes place after fermenting and is the time given to the beer to stabilize and age after fermenting.

Our stainless steel fermenters can be individually temperature controlled through glycol jackets and are mostly equipped with accessories such as over-pressure and under pressure valve(PVRV), CIP arm, sanitary sample valve, manway, etc.. The design of fermenters is based on our vast beer knowledge and especially the conical fermenter bottom and the fact that we combine fermentation and maturation in the same vessel is very important. When calculating your fermenting & lagering capacity and configuration, sufficient time fermenting and lagering to produce quality beers must be taken into consideration.

STANDARD PRODUCT FEATURES

▪SS Dished head

▪Butterfly valves, Sample valve,PVRV

▪Clamps and gaskets, pressure gauge

▪Interior shell: 304 stainless steel, thickness 3mm

▪Exterior shell: 304 stainless steel, thickness 2mm

▪Interior and exterior finish polished to a sanitary finish

▪Interior finish pickled and passivation

▪Dimple jacket cooling jackets

▪Exterior brushed finish

▪Fully welded exterior shell

▪60 degree cone bottom, with an average of 25% head space

▪Rotating racking port

▪Side/Top manway door

▪Dual zone dimple cooling jackets (3 or more on larger tanks)

▪2'' Polyurethane insulation

▪CIP arm and spray ball with a molding technology

▪Sanitary tri-clamp connections

▪Upgrade drain port size

▪Dry hop port