Pinch valve rubber sleeve High Pressure Type

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1000 |

| Place of Origin: | Anhui |

Company Profile

| Location: | Xuancheng, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Power: | Others |

| Brand Name: | FENGCHI |

| Production Capacity: | 1000 |

| Packing: | Fumigation-free export-grade wooden box |

| Delivery Date: | 10 days |

Product Description

Constructions applicable to various kinds of process conditions

High pressure sleeves are designed for high pressure applications. The high pressure sleeve features stronger fabric reinforcement and thicker construction compared to a standard one. The mating flanges are equipped with integrated O-ring seals to ensure a tight seal under high pressure applications.

Size range:

15~2000mm 1/2~80in

Pressure grade:

1~10Mpa 1:2 safety factor, which means bursting pressure is 2 times higher than the operating pressure.

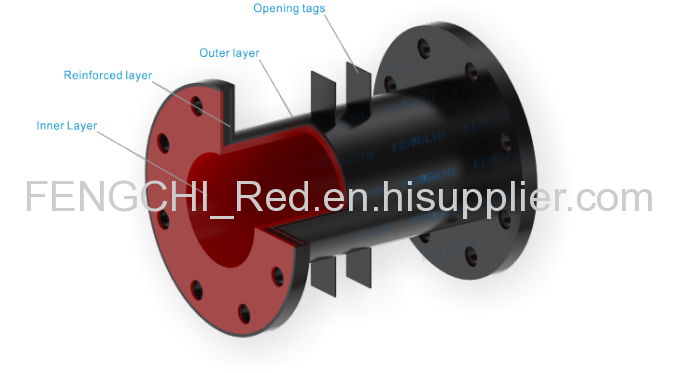

Analysis of construction:

Inner Layer: adopt various kinds of rubber materials or formulas in order to fit for the high demanding applications involving abrasion, corrosion or high temperature, etc.

Reinforced layer: the perfect combination of synthetic rubber and synthetic fibre technology forms a unique reinforced skeleton, which enables the sleeve to bear pressure and fatigue.

Outer layer: Using Natural Rubber to protect and reinforce the flexure resistance of valve sleeve.

Opening tags: the middle part of the outer layer is equipped with opening tags to solve the problem of fixation and tensile strength of the inner sleeve and actuator, also to ensure full opening of valves in all process conditions.