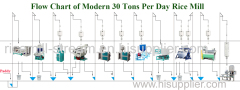

30 tons per day modern automatic industrial complete rice mill production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 30 tons per day |

| Place of Origin: | Shandong |

Company Profile

| Location: | Rizhao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | MCHJ30 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | STR |

| Usage: | clean and mill paddy into white rice |

| Production Capacity: | 30 tons per day |

| Packing: | Standard Export Package wooden box |

| Delivery Date: | 35 days |

Product Description

Introduction

30 Tons mini rice mill plant is the ideal choice for small farmers or small rice process factory. The output of white rice is about 30 tons per 24 hours.If work 8 hours,the output is about 10 tons.For paddy,it is about 40~45 tons per 24 hours,10~15 tons per 8 hours.

From feeding of paddy to packing of white rice,the whole process is done automatically,with high output,good quality,high efficiency and low broken rate.2~3workers can operate the whole factory.

Description:

MCHJ series is the leading unit in China to automatically process paddy with rational technology,scientific construction, and easy maintenance.

It is composed of elevator, pre-cleaning,de-stoner,rice huller, paddy separator,three passes of rice milling,white rice grading,color sorters, mist polisher,packing machine,control cabinet,etc.

Besides,this unit is equipped with all accessories,such as airing system to remove dust, and husk cyclone to prevent dust in work site.

If you have problem in electricity,we could offer best solution for you to save your money.For example,you can use husk to generate electricity power.

Further more,we can offer dryers,silos and rice flour machine for you.

If you like,we would design the whole factory for you according to your land area.

Basic Rice Milling Processes :

Pre Cleaning | Removing all impurities and unfilled grains from raw paddy |

De-stoning | Separating small stones from paddy |

Husking | Removing husk from paddy |

Husk Aspiration | Separating the husk from brown rice/ unhusked paddy |

Paddy Separation | Separating the unhusked paddy from brown rice |

Whitening | Removing all or part of the bran layer and germ from brown rice |

Polishing | Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of milled kernel |

Color Sorting (Optional) | Removing foreign materials such as colored, broken, immature and insected grains from milled rice |

Grading | Separating small and large brokens from head rice |

Weighing and Bagging | Preparing the milled rice for transport to the customer |