Customized external gear slewing drive slew drive used on heavy machinery and equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 100pcs per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | S-III-O-0555 |

|---|---|

| Means of Transport: | Rail, Ocean, Air, Land |

| Processing: | Forging |

| Shape: | Others |

| Standard or Nonstandard: | Standard |

| Material: | Steel |

| Tooth Profile: | Spur Gear |

| Brand Name: | U-TRSM |

| 3D model: | Yes |

| Brand: | U-TRSM |

| Place of Origin: | Luoyang, China |

| Material: | 42CrMo/50Mn+nodular cast iron+other steels |

| Warranty: | 1 year |

| Feature: | Spur gear slewing drive, high speed, without self-locking |

| IP Grade: | IP65 |

| Applicable Industries: | Energy & Mining, Machinery equipment |

| Color: | According to customers' needs |

| Service: | Design, Manufacturing, Customized |

| Production Capacity: | 100pcs per month |

| Packing: | non-fumigation wooden box |

| Delivery Date: | 30-60days |

Product Description

1. Company introduction

Unique Transmission Equipment (Luoyang) Co., Ltd. is an innovative technology company that designs, develops and produces slew drives and Slewing rings. We have a wide range of standard series products to choose from, we also focus on customized slew drive and slewing rings solutions.

Since its establishment, Unique Transmission has won the trust and support of many customers with its high-quality products, excellent slewing scheme design capabilities and quick response services. Unique Transmission can provide not only slew drive products and design solutions, but also provide motors, hydraulic motors and other accessories, as well as various machining products.

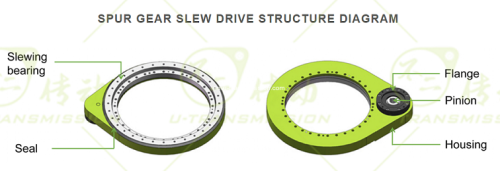

2. Spur Gear Slew Drive Introduction

Spur gear slewing drive is composed of slewing bearings, gears, housings, adapter flanges, support bearings, seals and other components. After reasonable design, component manufacturing, debugging, assembly and other processes, the products have the ability to withstand axial force, radial force, tilting moment torque and at the same time has a certain gear ratio, referred to as slewing drive.

Our spur gear slew drives has 3 series, 23 standard models in total to choose from, which can meet the needs of low load, medium load and heavy load. If our standard model products cannot meet your needs, you can also contact us and our engineers will design and customize a special spur gear slew drive for you.

We have created 3D models for all standard models of slew drive products. You only need to put this 3D model in your equipment model to verify the feasibility. If the standard slew drive model products are not available, our engineers with rich industry experience can design a new 3D model and work with you to design an ideal slewing transmission solution.

3. Dimension Details (You can download our catalogue to check more code details).

Model: S-III-O-0555

Type: external gear spur gear slewing drive

Slewing drive gear ratio: 5.80

Rated output torque: 22KN.M

Rotation center diameter: 555mm

Total height with adapter flange: 142mm

Gear backlash ≤0.3mm

S-III-O-0555 external gear spur gear slewing drives are used in heavy machinery and equipment to rotate workpieces. The slewing drives have a small load, but have a large tilting moment during use. The installation space of the equipment is relatively limited, slewing drives with a large slewing center diameter cannot be used. After comprehensive consideration, the model 0555 of the heavy-duty series was finally selected.

Heavy-duty series slewing drive slewing bearings adopt thickened design, steel balls adopt larger specifications, housings adopt thickened design, flange positioning pins adopt reinforced design, these designs can significantly increase the slewing drives'tilting moment, pinions and gear rings adopt teeth with a modulus of 8 and the teeth are quenched to increase the wear resistance and impact resistance of the tooth surface, which is suitable for customers' frequent start and stop conditions. The customer's motor flanges are special. If want to connect with our slewing drives directly, can only be realized by embedding bolts into the slewing drive flanges.

The technical team of Unique Transmission likes to have in-depth communication with customers, communicate with customers quickly and effectively during the design process, provide customers with reliable, practical and cost-effective solutions. If you need a design solution for rotation, please do not hesitate to contact us.

4. Packing Way

1. Apply anti-rust oil on slewing drives

2. Using wrapping belts to package the slewing drive

3. Place the packaged slewing drives to the plywood cases

4. Using pearl cotton to fix the slewing drives in the boxes and confirm the products will not move during transportation

5. Using packing belts to pack the wooden cases

6. Stick the shipping marks to let our customers identify goods easily.

5. Application Area

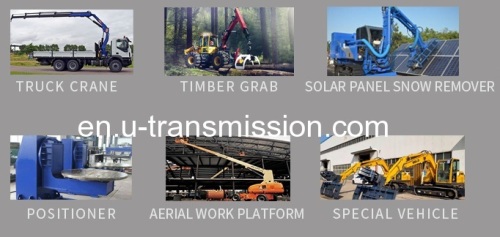

Spur gear slew drives applications mainly include industrial robots, machine tool turrets, cranes, truck-mounted cranes, automated production lines, light machines, radar cars, positioners, flexible bending machines, grass grabs, solar panel snowplows, forestry machinery, agricultural machinery and other fields. You can also check our mounting videos to learn how to use it.

6. Transportation: By sea/ air/ rail/ road/ TNT/DHL/UPS/Fedex, all acceptable.

7. Contact information

Unique Transmission Equipment (Luoyang) Co.,Ltd

Address: No.22 Binhe Road, New & High Tech Industry Development Zone,

Luoyang Area Of China(Henan) Pilot Free Trade Zone, 471000