700KW 1400KW 2100 KW 2800KW Industrial Gas Oil Fired Hot Water Boiler Price for swimming pool

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | CWNS2800 |

|---|---|

| Means of Transport: | Ocean, Land |

| Output: | Hot Water |

| Type: | Natural Circulation |

| Structure: | Fire Tube |

| Fuel: | Oil-fired |

| Pressure: | Low Pressure |

| Style: | Horizontal |

| Usage: | Industrial |

| Brand Name: | Jinzhenboiler |

| Item: | gas diesel oil fired hot water boiler |

| Capacity: | 350kw to 14000kw(0.35MW to 14MW) |

| Hot water temperature: | 85 /95/115 degree |

| Structure: | three pass Fire Tube Wet Back boiler |

| Boiler fuel: | natural gas, lpg,lng,cng,biogas, diesel oil,heavy oil |

| Application: | Hotel,School,Hospital,Greenhouse,Farms,Pool |

| Production Capacity: | 100sets |

| Packing: | wooden package |

| Delivery Date: | 28 days |

Product Description

700KW 1400KW 2100 KW 2800KW Industrial Gas Oil Fired Hot Water Boiler Price for swimming pool

CWNS series gas/oil fired hot water boiler is horizontal three pass fire tube wet back full automatic steam boiler. It normally suitable for 0.35MW to 14MW capacity, use all kinds of gas and oil fuels,such as natural gas, lpg,lng,cng,city gas,biogas, diesel oil,heavy oil.

General features of WNS series hot water boiler

1. horizontal , gas & oil fired , water tube, industrial and low pressure;

2. wetback and three-backhaulstructure design;

3. With high efficiency economizer, the thermal efficiency can reach more than 90%.

4. The spring-loaded type explosion door ensures the boiler safety

5. The removable smoke boxfacilitates the maintenance

6. Internal micro positive pressure combustionreduces the low temperature corrosion.

7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

Main Features

A. Simple and intuitive operation interface

With touch type as the control programming, can at any time display fan, water pump, oil pump and other operating conditions and flame stepless change state, with a full range of online help, easy to operate, suitable for any cultural levels of people.

B. The operation is fully automatic and unmanned

With automatic flame proportional regulation, automatic furnace purge and flame, wind pressure, oil return pressure automatic detection functions.In addition, the steam boiler also has continuous automatic water supply, surface discharge automatic control and water level low limit, high limit automatic detection functions.

C. Automatic system start and stop

It has the functions of automatic start and stop setting, time correction, regular start and stop, multiple priority start and stop, pre-setting of working day and rest day, automatic judgment of rest day, etc.

The boiler has the standby function when the pressure is higher and the self-starting function when the pressure is lower.It has the function of automatically stopping the furnace when the water level is too high and releasing water before starting again.

D. High reliability of the system

It has the interlocking protection function of oil pump, water pump and fan overload, ignition failure, abnormal flameout, fan no wind, gas leak detection failure, gas leak, gas pressure too low, smoke temperature and gas pressure, and oil return pressure too high fault.Have operation password, system debugging password, user program OEM protection password.In addition, the hot water boiler also has the interlocking protection function of circulating water vaporization, circulating water determination, water outlet temperature exceeding and other faults.

E. Rich extension functions

1. Multiple boilers can be networked, and the number of boilers can be automatically selected and the load of each boiler can be allocated without setting the main console.

2. The touch screen has remote monitoring function.

3. Through telephone dial-up network, our company can monitor the operation of each boiler at any time.

Technical parameter

Boiler model | WNS0.35 | WNS0.7 | WNS1.4 | WNS2.1 | WNS2.8 | WNS4.2 | WNS5.6 | WNS7.0 | WNS10.5 | WNS14 | |

Rated thermal power(MW) | 0.35 | 0.7 | 1.4 | 2.1 | 2.8 | 4.2 | 5.6 | 7 | 10.5 | 14 | |

Rated work pressure(Mpa) | 0.7/1.0/1.25/1.6 | ||||||||||

Output water temp.(℃) | 95/115/130 | ||||||||||

Return water temp.(℃) | 70 | ||||||||||

Thermal efficiency(%) | >97 | ||||||||||

Nox emission(mg/m3) | 120/80/30 | ||||||||||

Exhaust gas temp.(℃) | <60 | ||||||||||

Fuel type | diesel oil/natural gas/heavy oil/liquefied gas/city gas | ||||||||||

Fuel consumption | diesel oil | 31.6 | 60.4 | 122.8 | 192.3 | 246.1 | 367.1 | 490.2 | 593.6 | 936.5 | 1200.8 |

natural gas | 36.6 | 69.3 | 146.1 | 227.1 | 286.5 | 412.6 | 543.7 | 660.7 | 998.8 | 1330.7 | |

Transporation weight(t) | 2.65 | 4.66 | 6.53 | 7.3 | 8.1 | 15.1 | 18.2 | 25.6 | 29.1 | 47.8 | |

The running of the boiler realizes full-auto control:the water temperature of the exit is automatically adjusted::the autoignition procedure of the boiler is started ,multiple alarming and interlocking protection devices like deaquation,overheating and flameout are prepared to ensure boiler to run effectively,safely and reliably.

Application in chemical engineer ,lipin,petrifaction,plastic pasterm,weaving ,fiber ,carbon elements,atormic energy industry,paper making printing,timber,metal,automobile,construction,cement,electric,air conditioning and other area.

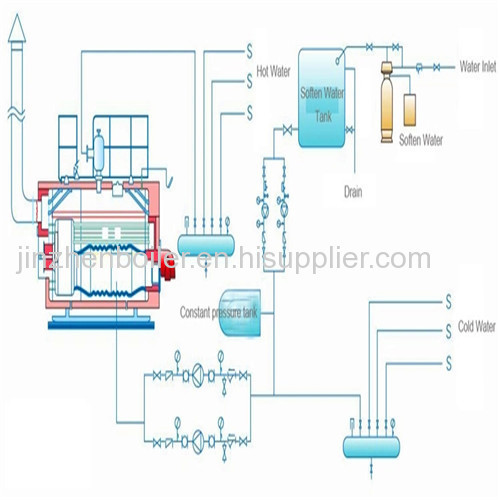

Boiler picture