10 ton Automatic feeding Stoker Grate Biomass pellet Coal Fired Steam Boiler For Textile Mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100set per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | DZL10-1.25 |

|---|---|

| Means of Transport: | Ocean, Land |

| Output: | Steam |

| Type: | Natural Circulation |

| Structure: | Water Tube |

| Fuel: | Coal-fired |

| Pressure: | Low Pressure |

| Style: | Horizontal |

| Usage: | Industrial |

| Brand Name: | JinzhenBoiler |

| Item: | Industrial Coal Fired Steam Boiler |

| steam capacity: | 10ton/h,10000kg/h |

| pressure: | 0.7/1.0/1.25/1.6/2.5Mpa |

| temperature: | 170/184/194/204/225C |

| Design fuel: | coal, wood, chips, pellet, husk |

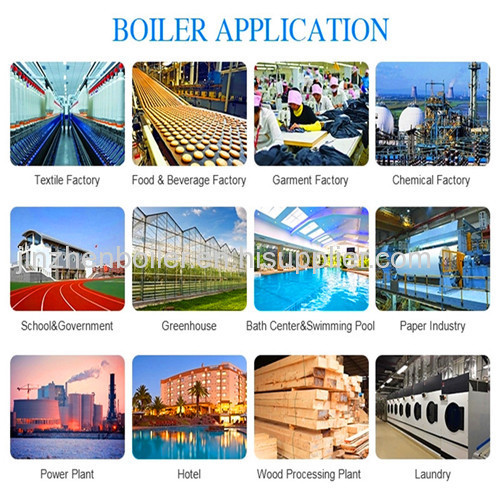

| Application: | rice mill, sugar mill, food and beverage, textile and Printing |

| boiler efficiency: | 88.5% |

| Production Capacity: | 100set per month |

| Packing: | wooden package |

| Delivery Date: | 30 days |

Product Description

DZL type horizontal biomass steam boiler

Specification model: 1 -- 20 tons

Thermal efficiency: 85%

Applicable fuel: biomass pellet

Application: medicine, chemical industry, light industry, textile, building materials, breeding, food and beverage, plastic foam, printing washing, rubber processing, paper making, wood processing, hotels, hotels, clothing, etc

The new type of environmental protection DZL type horizontal chain - fired coal fired steam boiler is a horizontal three - return water - fire tube boiler.Two fire tubes are arranged in the pot barrel, and both sides of the furnace chamber are equipped with light tubes and water wall tubes.The combustion equipment adopts light chain grate to realize mechanical addition of biomass, and is equipped with drum and induced draft fan to realize mechanical ventilation.The fuel falls on the grate from the biomass bucket and burns along with the grate, and the flue gas passes through the upper combustion chamber of the rear arch, enters the first bundle to the front smoke box through the upper smoke chamber of the back shed pipe, folds into the second bundle to the back smoke box from the front smoke box, and is introduced into the flue, dust collector and chimney through the induced draft fan, and finally exhausts to the atmosphere.The boiler automation level is high, the boiler feed water automatic regulation, high and low water level alarm, low water level interlock protection, lead, fan interlock protection.Boiler biomass, slag and other operation mechanization, reduce the labor intensity of workers, supporting a complete set of auxiliary machines.

DZL Automatic Coal Fired Steam Boiler features:

1.Maturity

One of the earlist manufacturers of fast-assemly thread pip chain grate boiler in China, In the past 10 years, the products have been replaced many times, more mature, similar products have produced more than 6000 units

2.Advance technolody

Adopt many advanced technology: threaded pipe, airfoil flue , Convex tube plate, the backwater towards high temperature tube plate, simple loop circuit, dust separated chamber, big furnace, compact structure so on.

3. Stable operation

The steam boiler has stable operation, low failure rate and never have safty accident.

Boiler can work 20 years.

4.Reliability

The only boiler factory have 20 0000fatigue test to boiler in China

5.Economy

High efficiency, energy saving, good economy.

6. High level Aumotic control system

The boiler automaticon lelvel is high, the boiler feedwater automatic regulation, high-low water level alarm, low water level interlock protection, fan interlock protection, automatic feeding fuel, automatic water feeding, automatic ash remove function.

Boiler Specification

Model | DZL1-0.7-AII | DZL2-0.7- AII | DZL4-1.25- AII | DZL6-1.25- AII | DZL8-1.25- AII | DZL10-1.25- AII (Assembly) | DZL20-1.6-AII | |

Steam Capacity | 1 | 2 | 4 | 6 | 8 | 10 | 20 | |

Steam Pressure | 0.7/1.0/1.25 | 1.25/1.6 | ||||||

Steam Temperature | 170/184/194 | 194/204 | ||||||

Feed water Temperature(℃) | 20 | 20 | 20 | 20 | 20 | 70 | 70 | |

Heating Area(m2) | Body | ~33 | ~50 | ~100 | ~170 | ~200 | ~250 | 502 |

Economizer | 10.56/10.56/20.7 | 27.6 | 52.48/33.12 | 87.2 | 98 | 174 | 382 | |

Effective Grate | 2.22 | 2.22 | 4.1 | 5.5 | 7.95 | 9.75 | 23.9 | |

Fuel Type | II Bituminous Coal, Lower Heating Value Q≈21000KJ/Kg | |||||||

Fuel Consumption (kg/h) | ~151 | ~302 | ~600 | ~880 | ~1150 | ~1450 | ~1160 | |

Exhaust Gas Temperature(℃) | 135-145 | |||||||

Thermal Efficiency (%) | 83-85 | |||||||

Weight of Biggest Part for Transportation(t) | 17 | 23 | 25 | 35 | 45 | 33(Up Part) | 50(Up Part) | |

Overall Dimension of Boiler Assembled | 5.1×2.2×3 | 5.5×2.3×3.3 | 6.6×2.6×3.6 | 7.5×2.9×3.8 | 8.1×3.1×3.8 | 7.7×3.2×3.6 | 11×3.24×3.54 | |

Boiler picture